The Thingiverse object that I chose was a cable organizer created by user @tjmck. It’s designed to hold larger cables such as ethernet or phone cords. I chose this design because it was something that I personally need, but I think I could improve upon the design. I’d want to make it more friendly for smaller wires.

To improve upon the original design, I’d want the object to be able to hold wires of any size without any external means. I created “clips” so that I could stick the wires in without them coming back out unless I lifted the clips.I didn’t like that it was just a circle and I’d want to be able to stick the organizer on a desk or something else so I can easily access the wires if I needed to so I created a base for it. I thought the waves would limit the amount of cables I could put in too much so I decided to keep the compartments in a line.

F|F Iterations

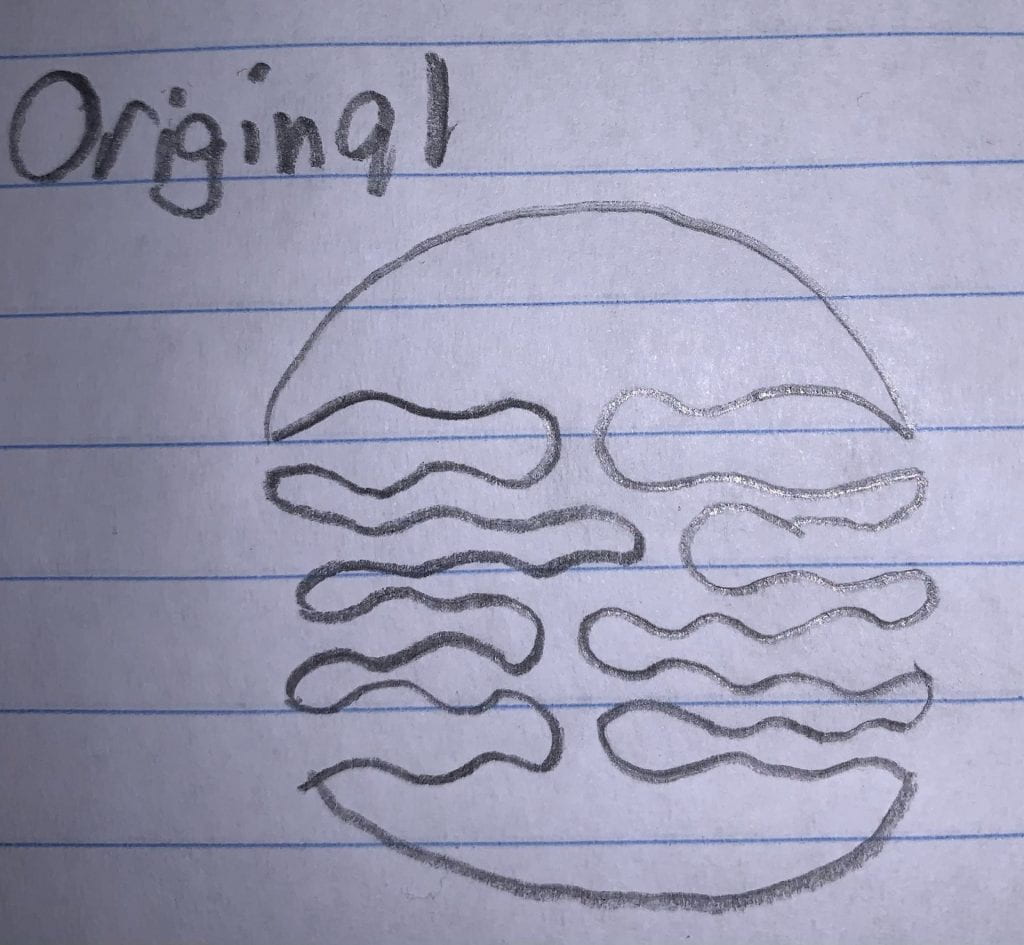

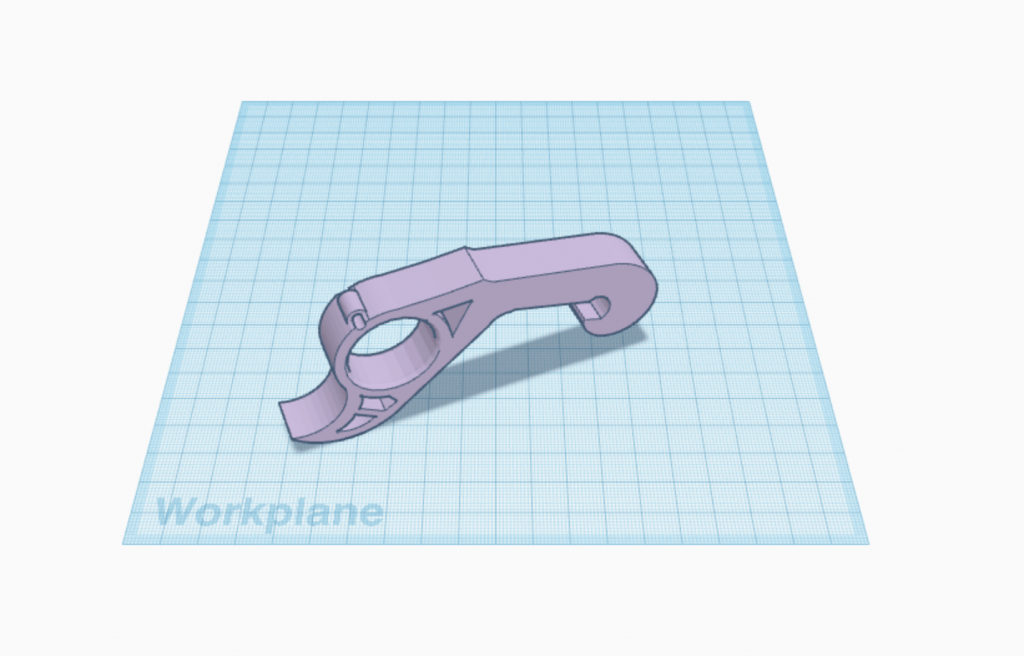

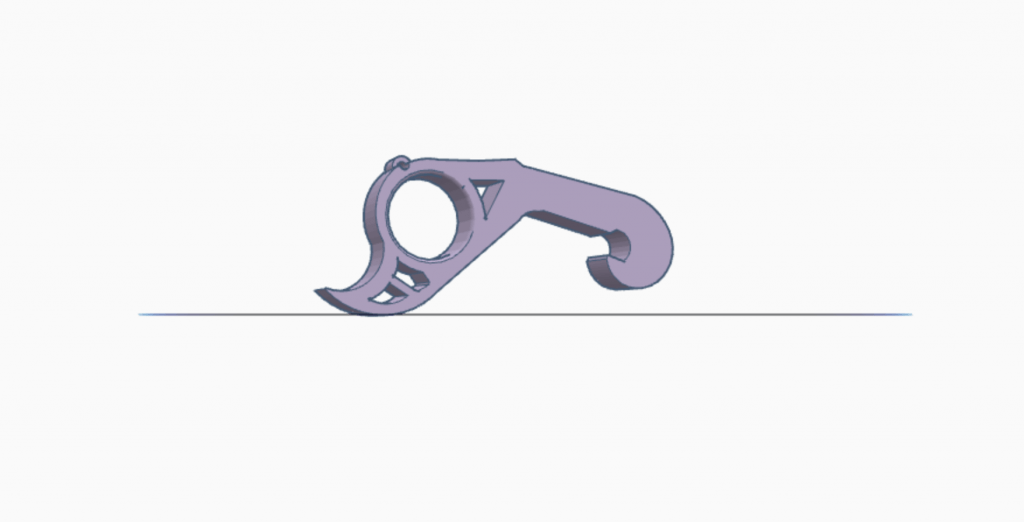

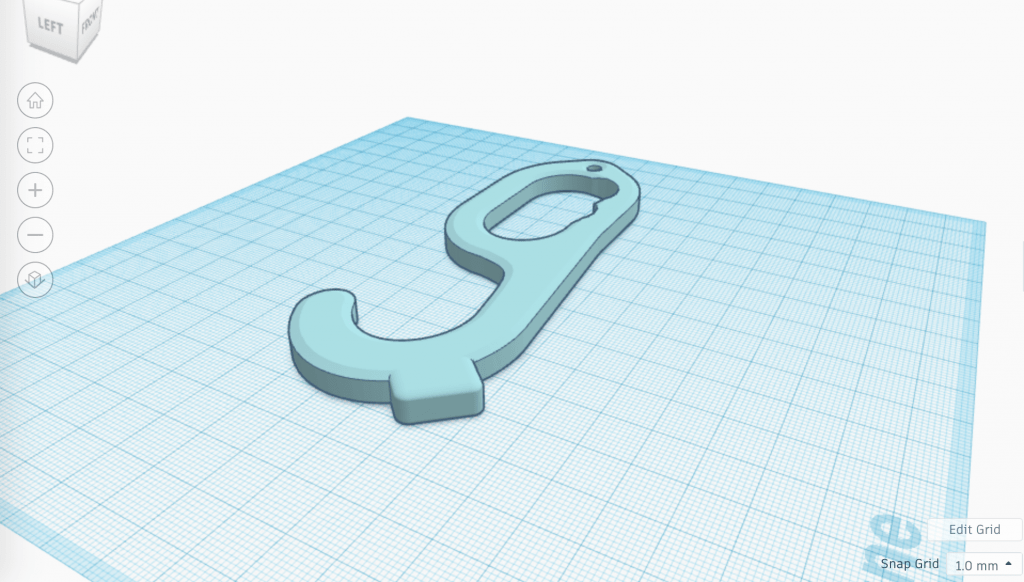

Original Object: This cable organizer, created by Thingiverse user @tjmck, is designed in a circle shape with wavy patterns on the inside with the intention on holding different size cables.

Below is a video of how the print is supposed to be used.

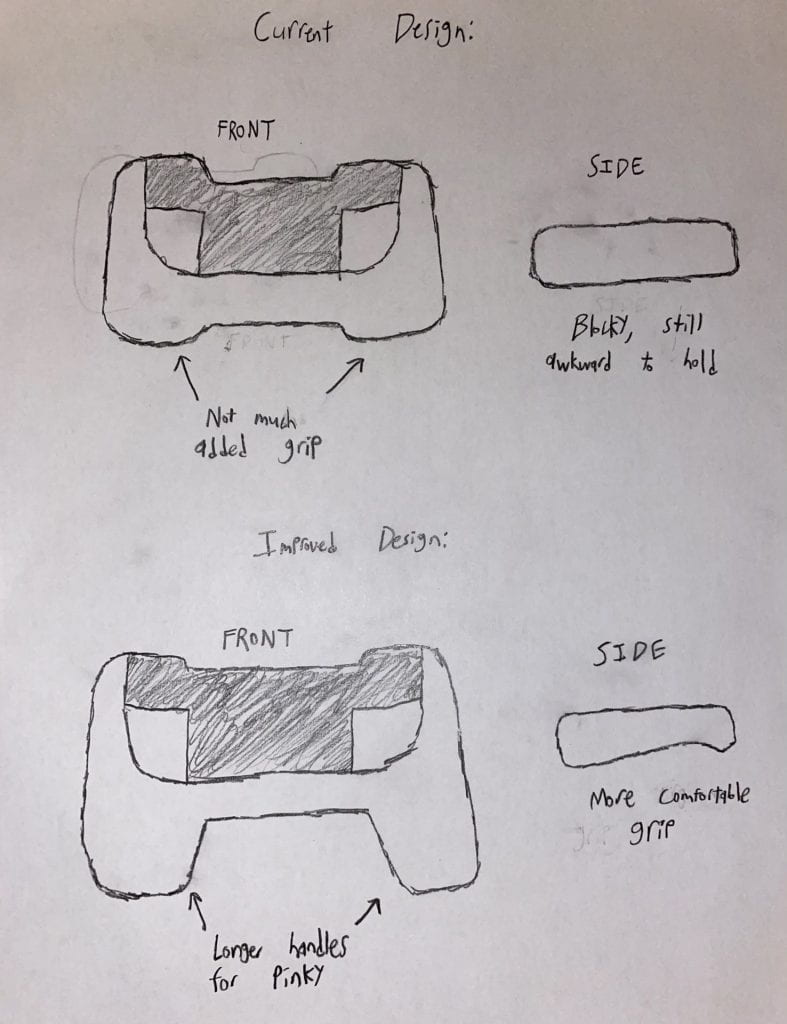

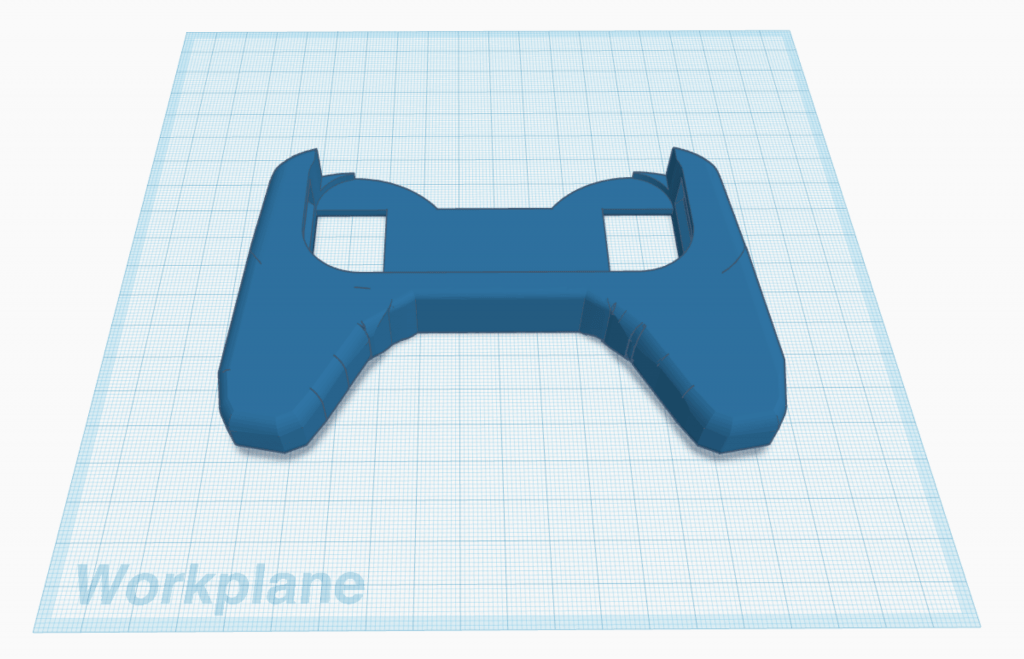

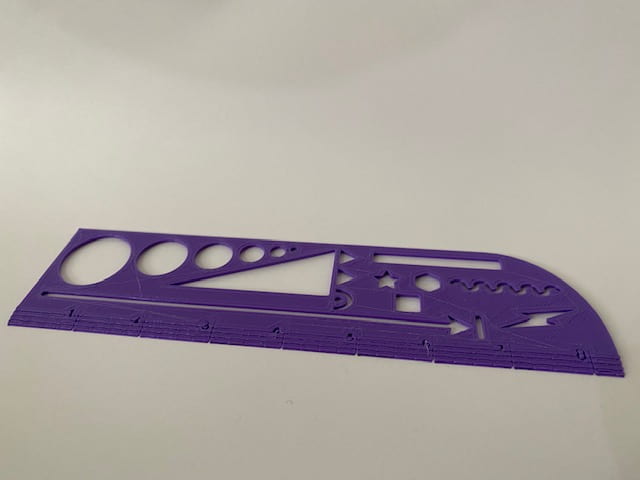

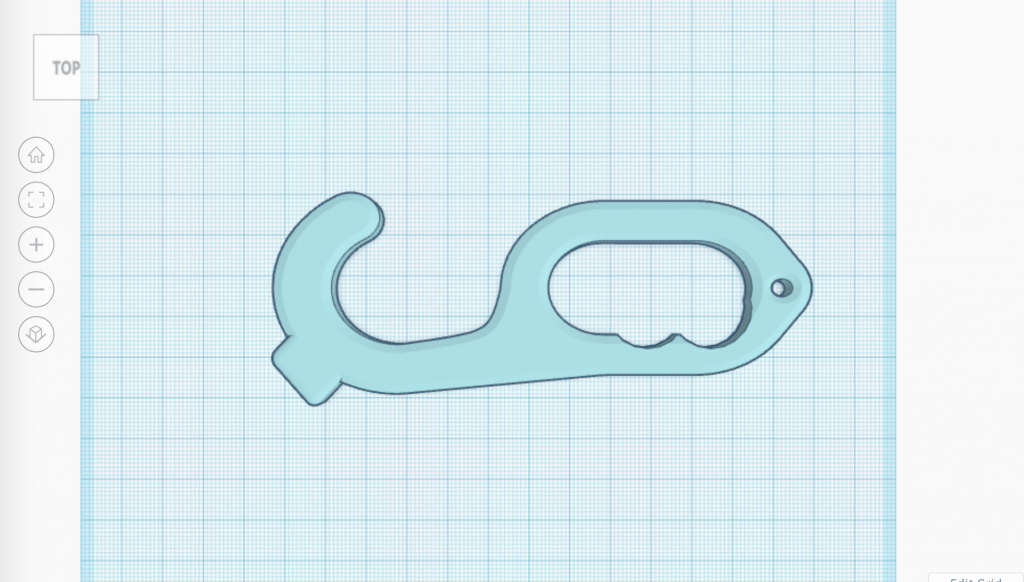

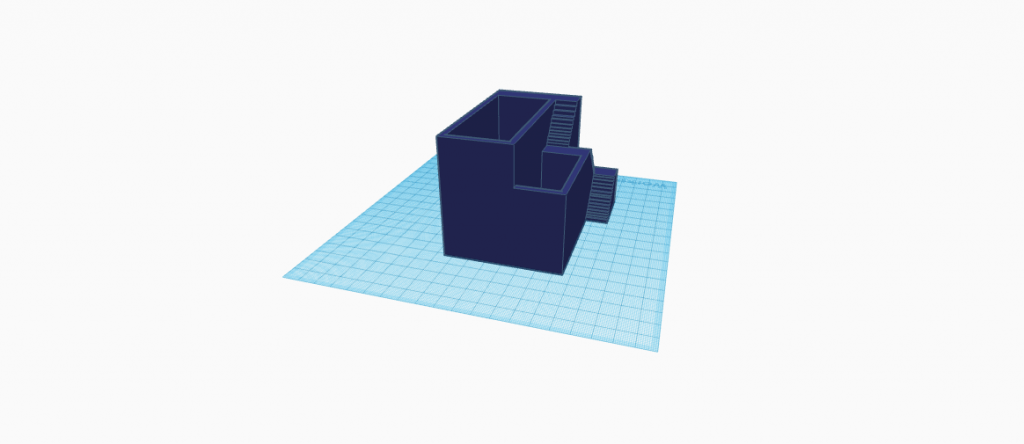

My First Iteration: I decided that since the original had trouble with keeping the wires in place and not having enough size variation for different cable thicknesses, I should try to address those issues. Below is what I came up with.

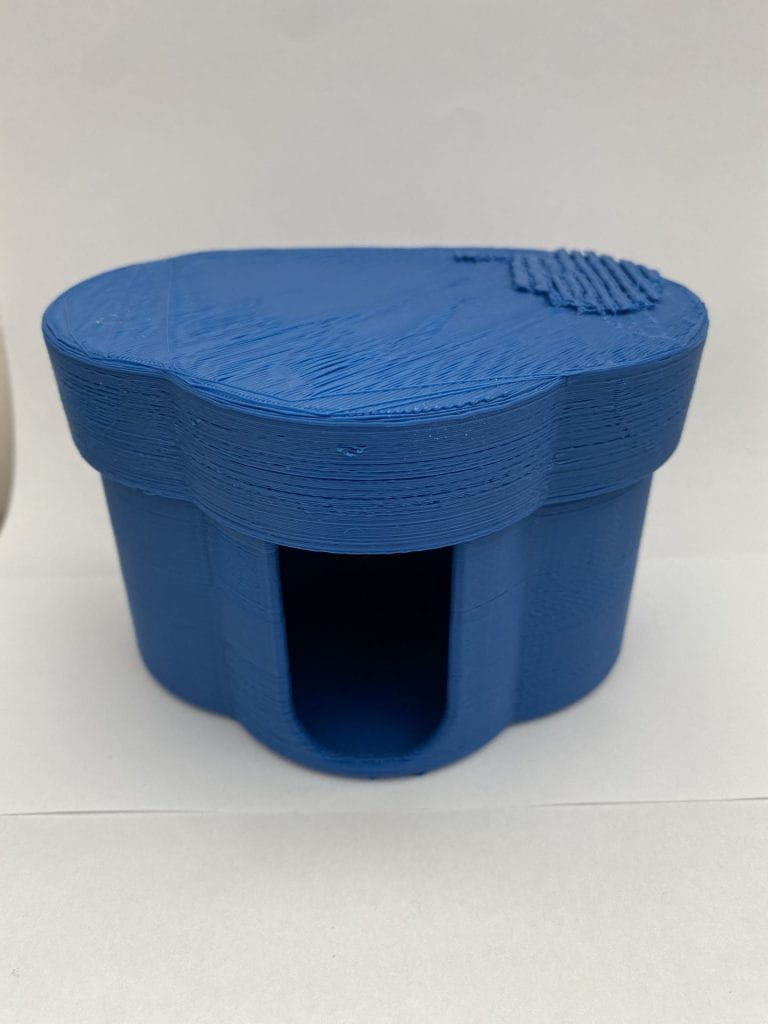

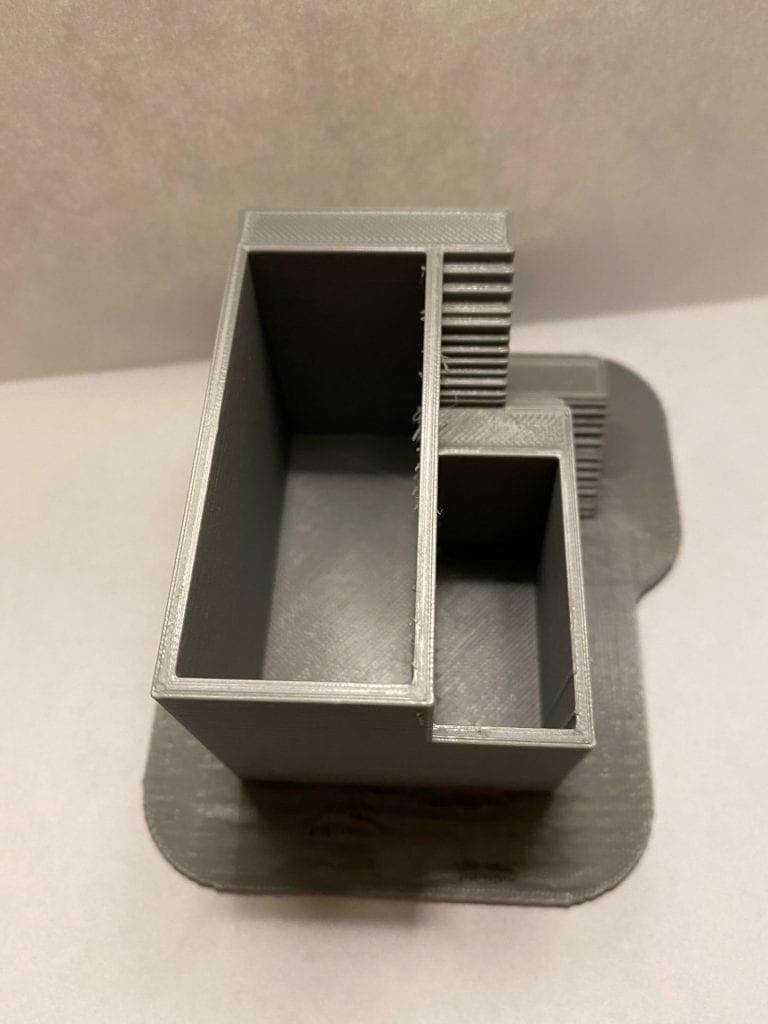

The intentions I had behind this design included slipping the wires underneath the wedges so that once the wire was in there, it wouldn’t move. I made the base flat so that way I could tape it down to a surface instead of leaving it hanging. I tried to give each of the spaces different sizes to allow for varied wire sizes. Below is what the print looked like in real life.

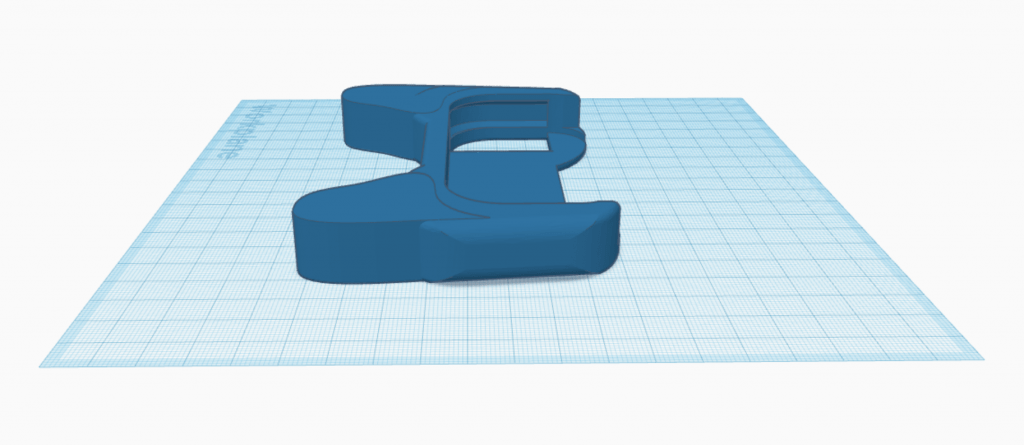

Unfortunately something went wrong during the beginning of the print but it sorted itself out afterwards. I think if I had made a base it wouldn’t have came out so strange. I was surprised by the durability of the plastic when I was bending it to insert wires. I accomplished the goal of having the wires stay inside the organizer. I regret making so many compartments though, as it took away space that I could’ve used to make less of them but bigger. I didn’t accomplish my goal of being able to hold larger wires so I’ll try to improve that design again in the future.

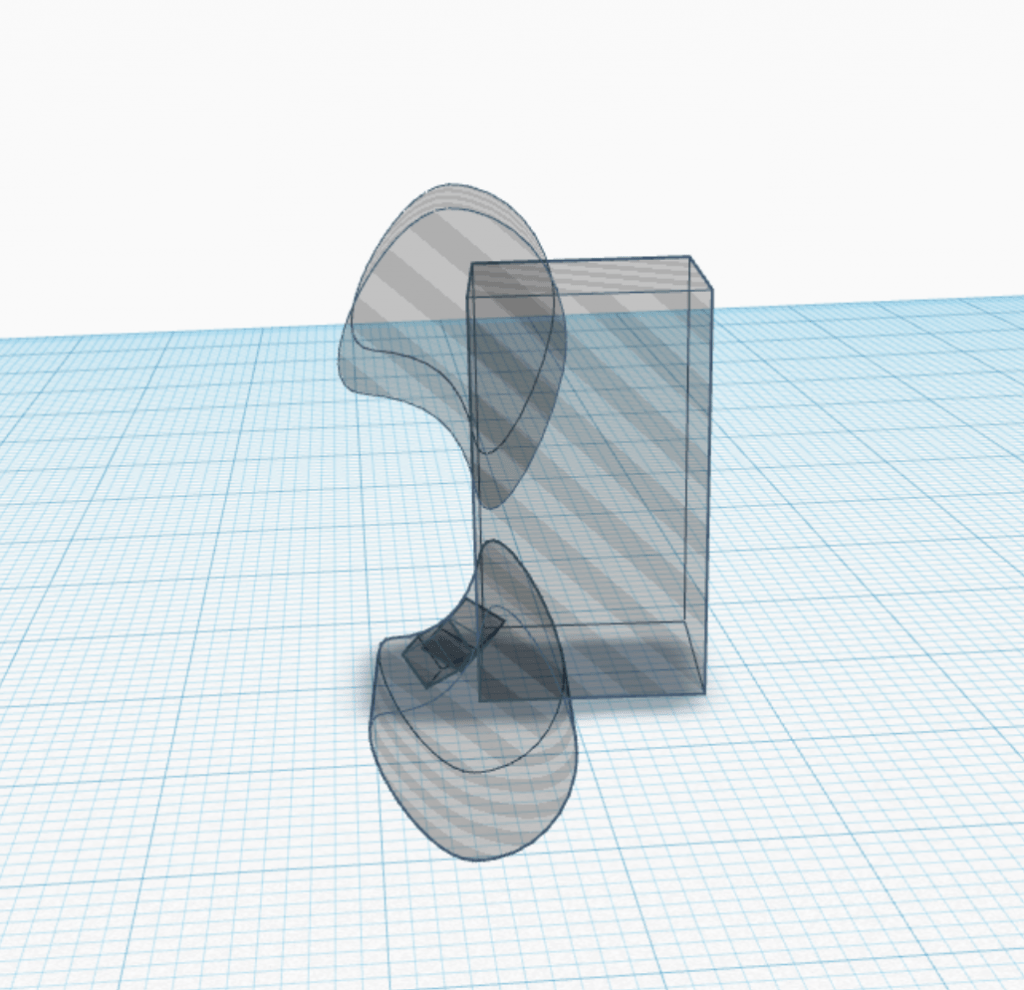

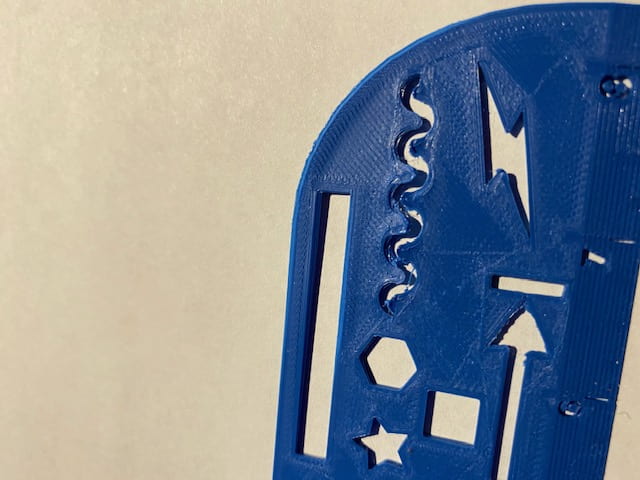

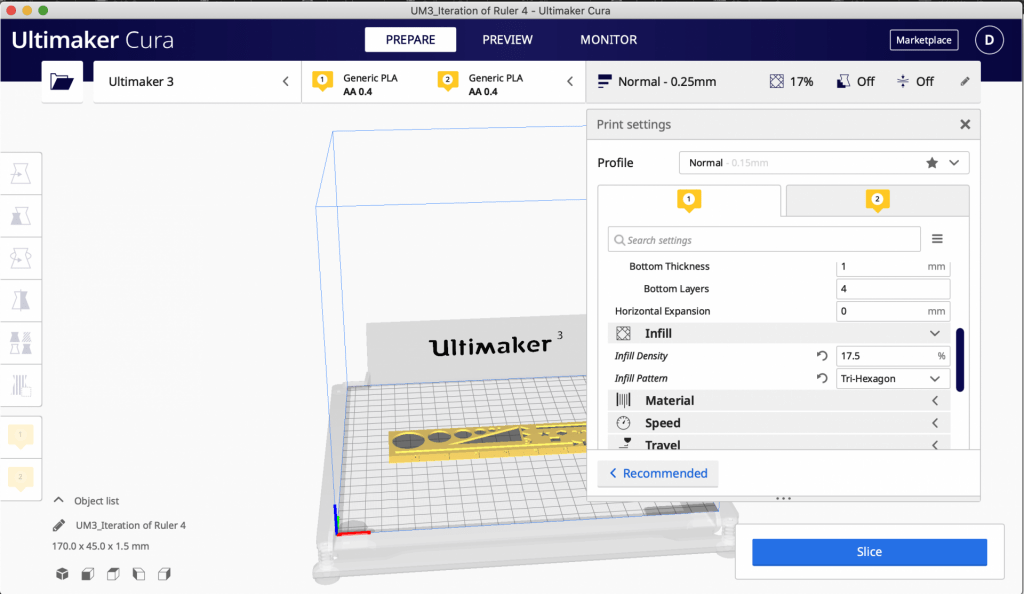

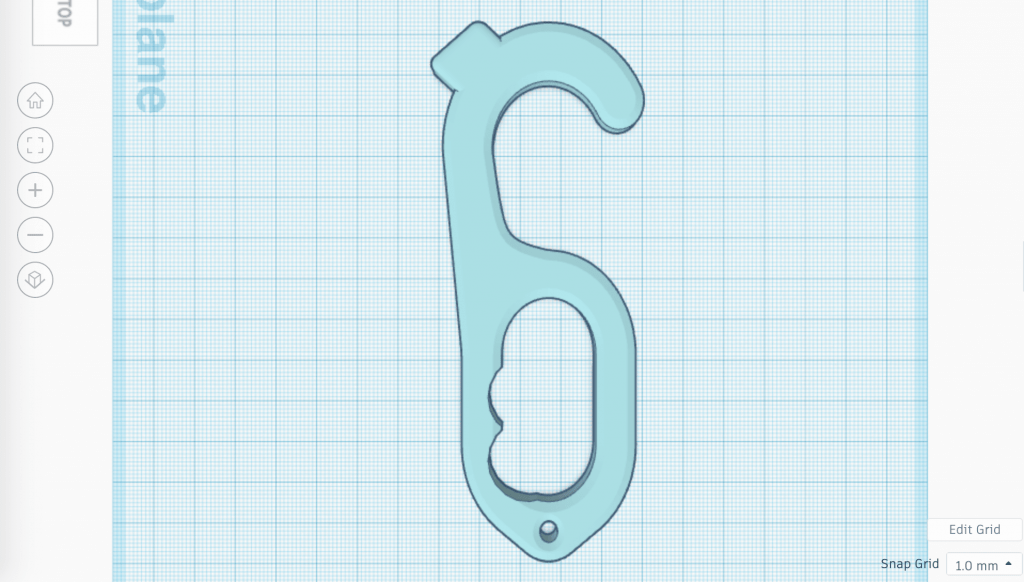

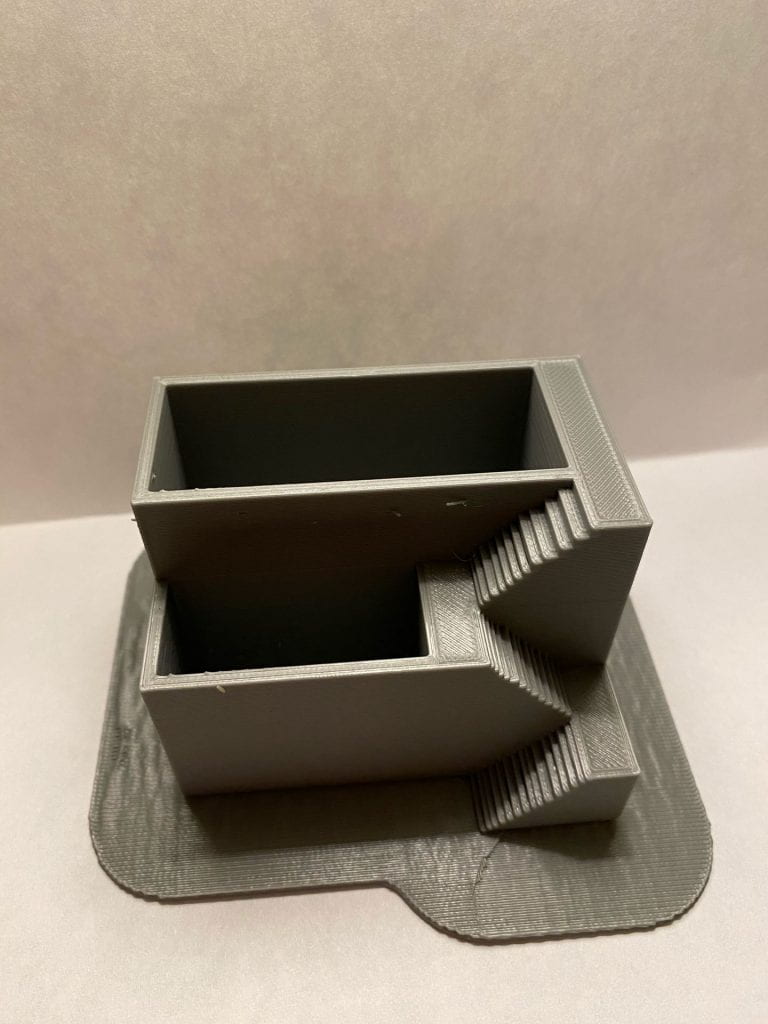

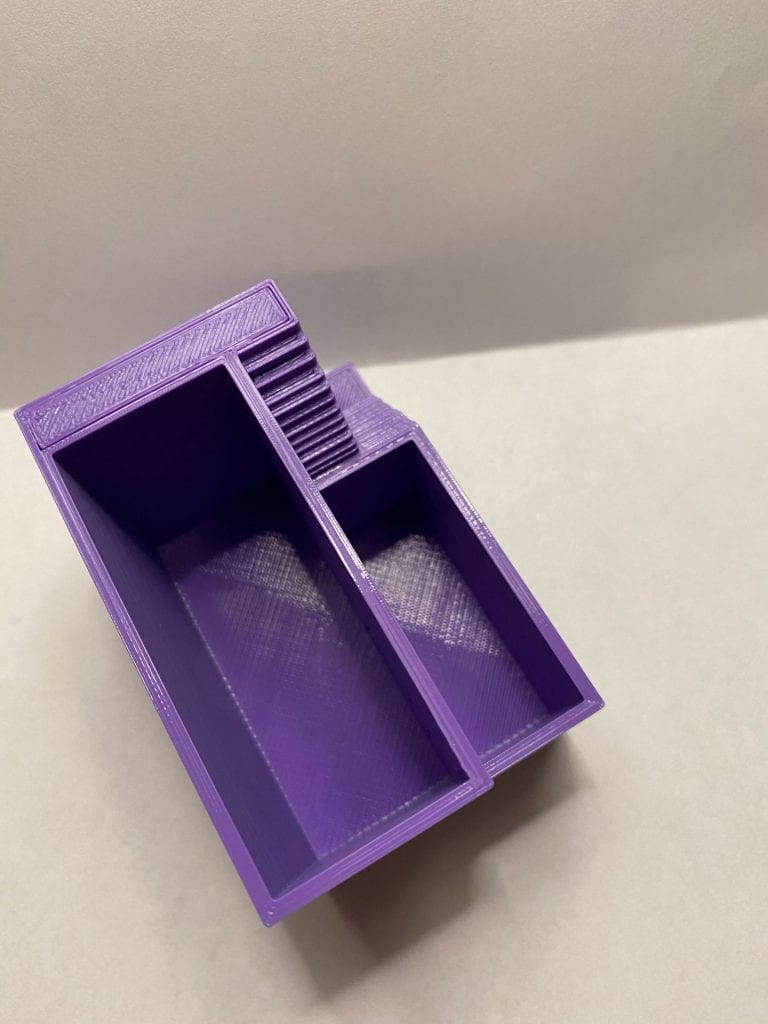

My Second and Final Iteration: Since the first iteration that I printed was affected by some printer issues, I used a different printer this time to avoid that happening again. I made some very slight changes to the first iteration. I deleted one of the wire compartments so that I could make space for compartments that would allow for thicker wires to be inserted. I also increased the infill density from 20% to 40% to make sure that it was stronger and wouldn’t snap if a wire was shoved in there.

This model did the job I wanted it to do perfectly. I unfortunately don’t have any wires thick enough to demonstrate the bottom portion, but the rest of the compartments work perfectly. The wires slip into the side with just a little effort and stay there unless they’re pulled out. Thanks to the wedge shapes, it’s easy to pull them out as well. My biggest concern with this entire build was that it would snap into pieces but after applying more force with my fingers than it would ever need to deal with, I’m confident that this is quite a strong bit of plastic, and I will definitely be using it next time I move my things around.