Research

When considering what functional object that I wanted to inject whimsicality and playfulness into, I began brainstorming by considering the things around me which I most frequently use. This led me to my pencil holder. A pencil holder is a commonly owned household item, providing users with great organizational benefits. In order to save desk space, users can insert any type of pen, pencil, marker, or even scissors into it. This item is generally distributed in boring and uncreative shapes, such as cylinders or rectangles. They are fairly straightforward items, found in most department and office supply stores. In order to house writing utensils, the shapes are hollow and lid-less. My current pencil holder isn’t even designated for its job, as it is merely a cylindrical coffee mug with no sense of inspiration or playfulness.

Concept

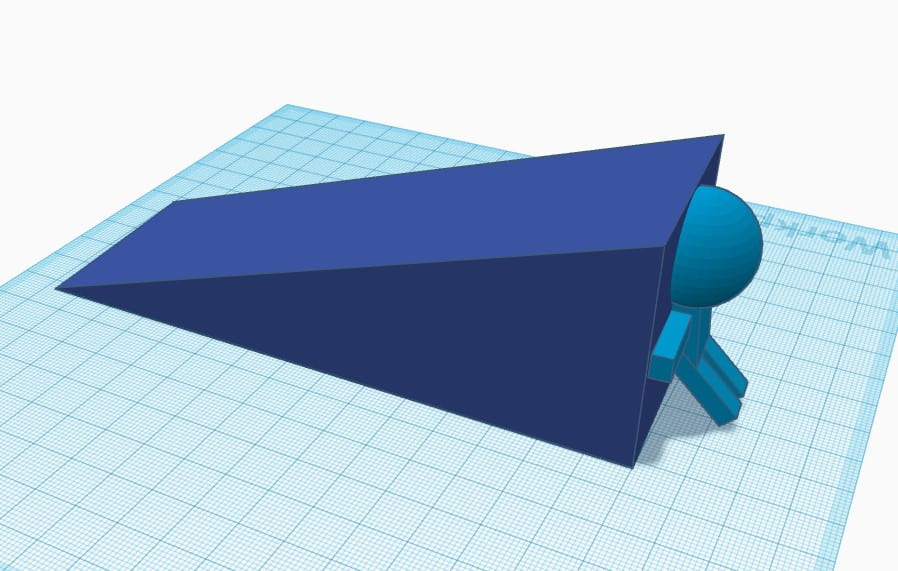

To make this object more playful, I decided that I would ironically intertwine the object’s functionality and purpose with its literal name. I plan on designing the pencil holder in a way that emulates a hand holding a pencil. To do so, I will couple a pencil container, representing a pencil itself, and a base––the hand. The hand will position the holder at a slight angle, allowing the stored writing utensils to be more accessible to the user. Instead of an eraser at the end of the ‘pencil’, there will be a hollow opening into which users can drop their pens and pencils into. This tongue-in-cheek design is a good representation of my humor, and it will also serve me very well, as I lack adequate storage for my writing utensils. Although one can hold their pencils in almost anything that is hollow and has a hole on the top, I am seeking to add a touch of my creativity into this simple yet functional object.

Iterations

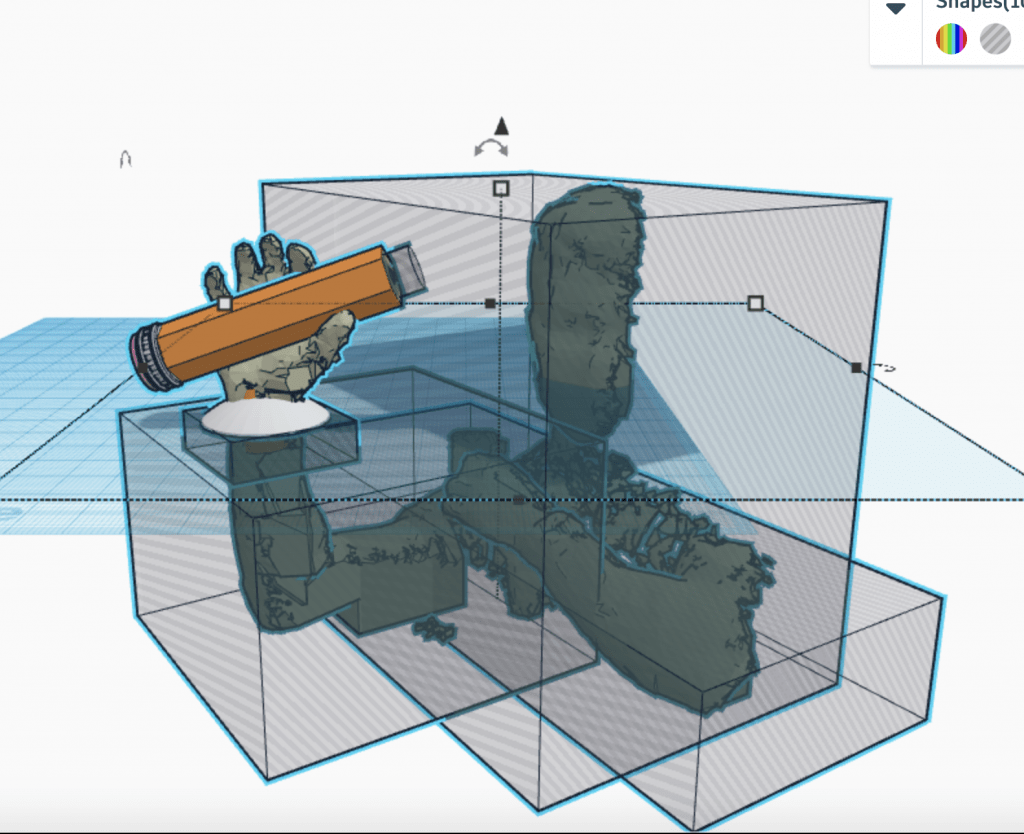

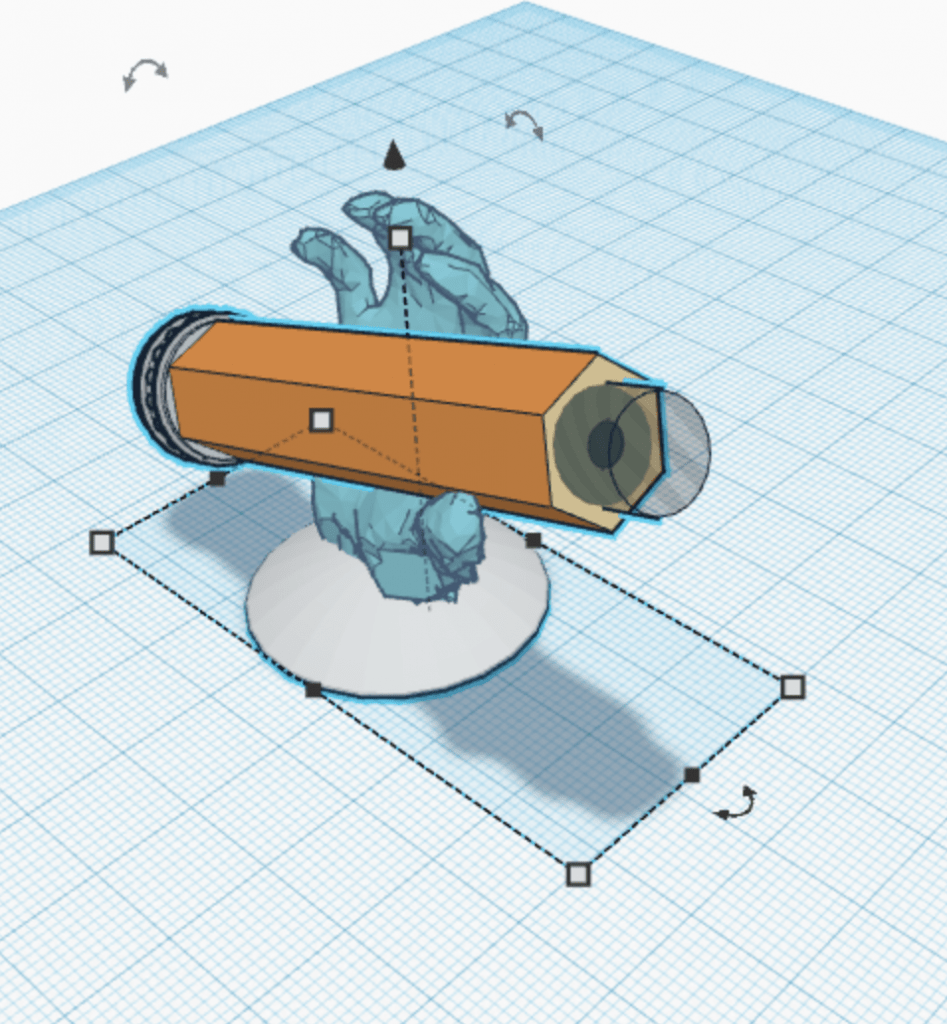

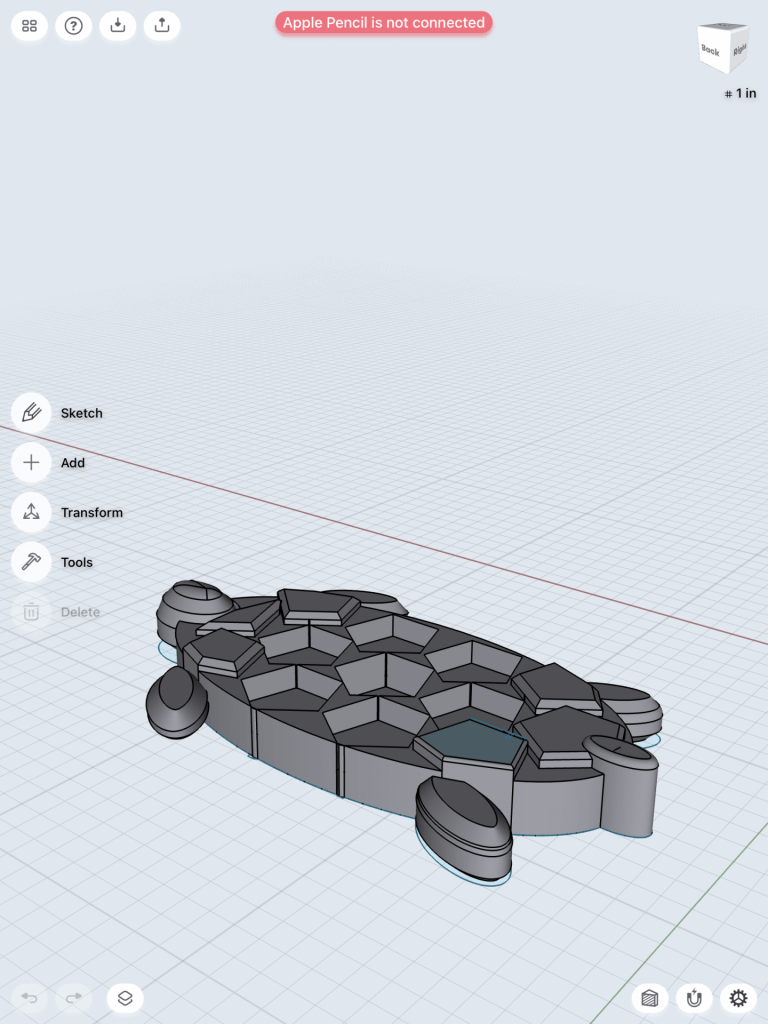

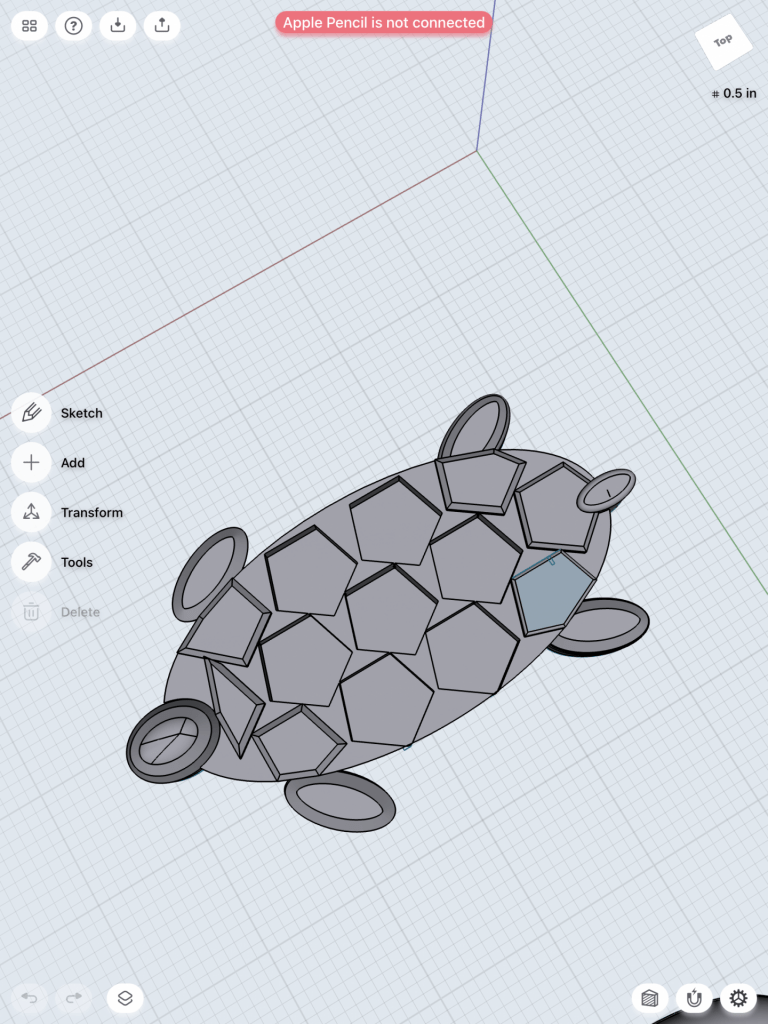

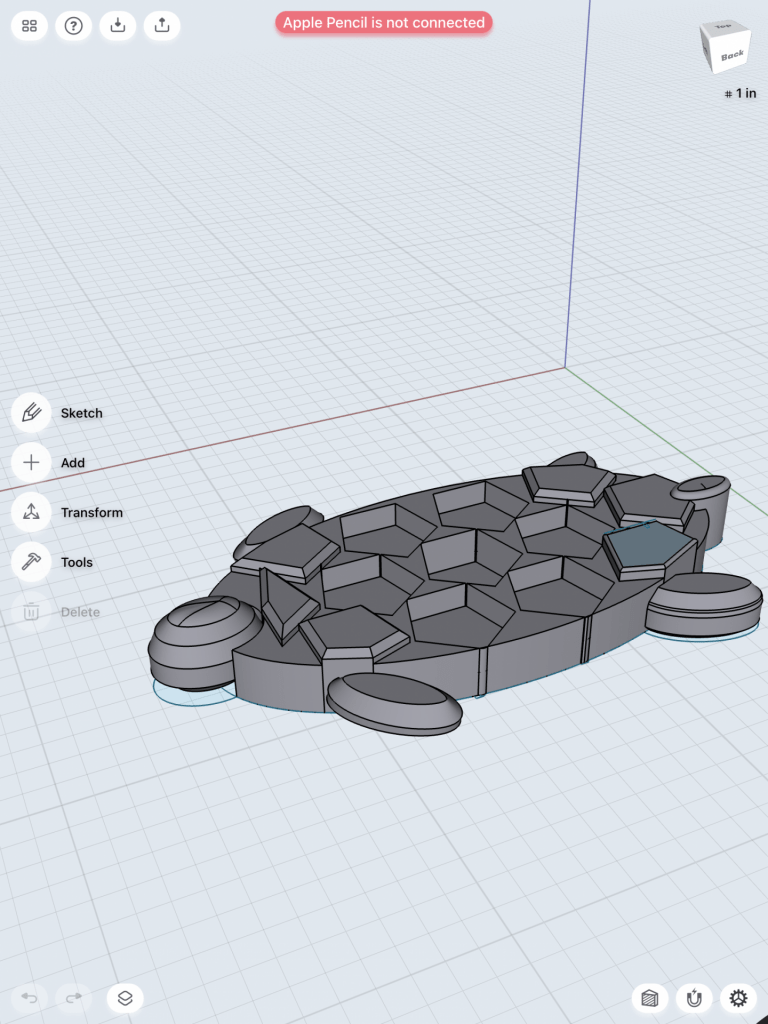

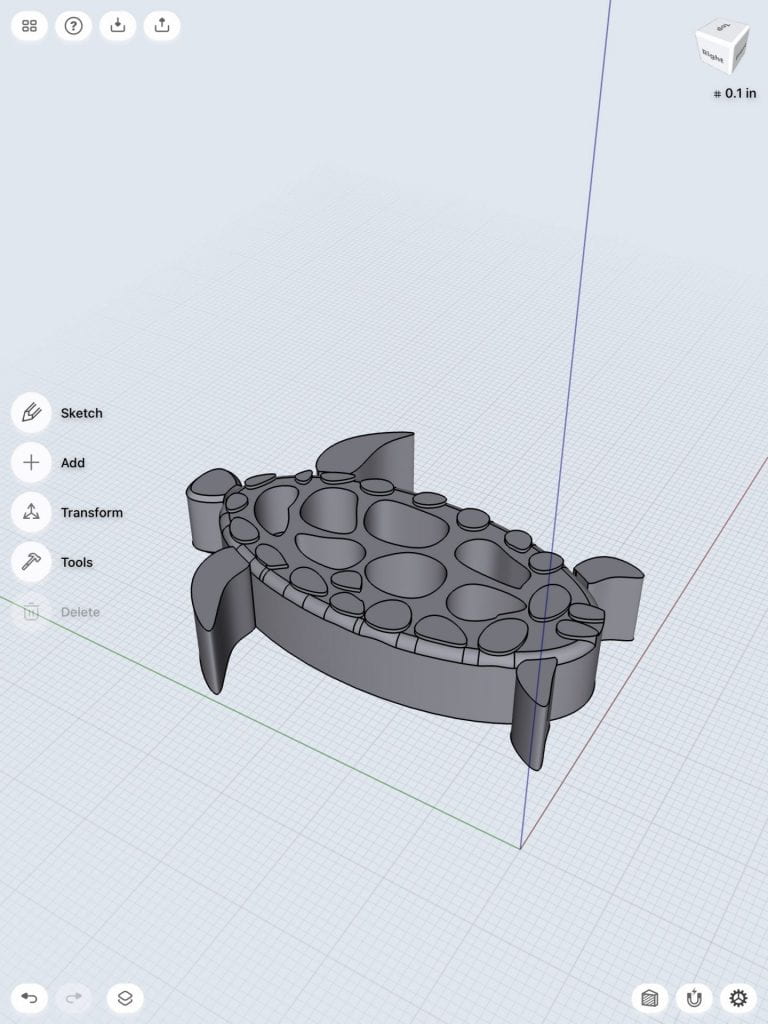

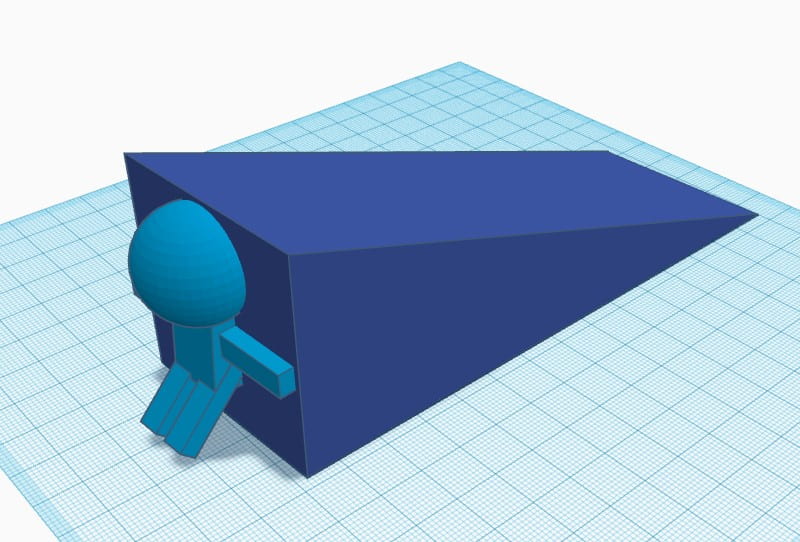

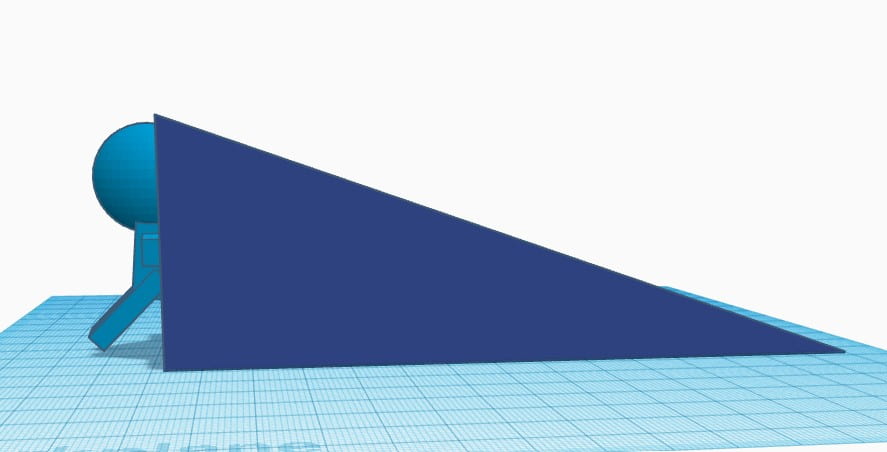

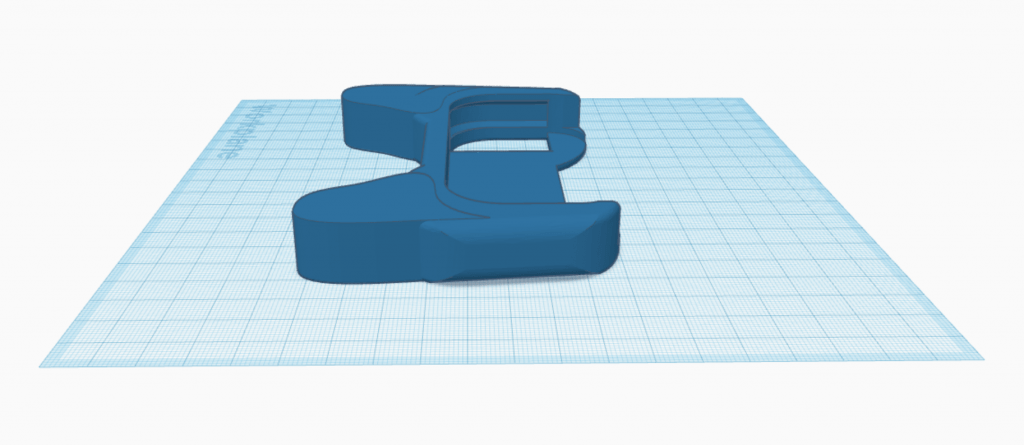

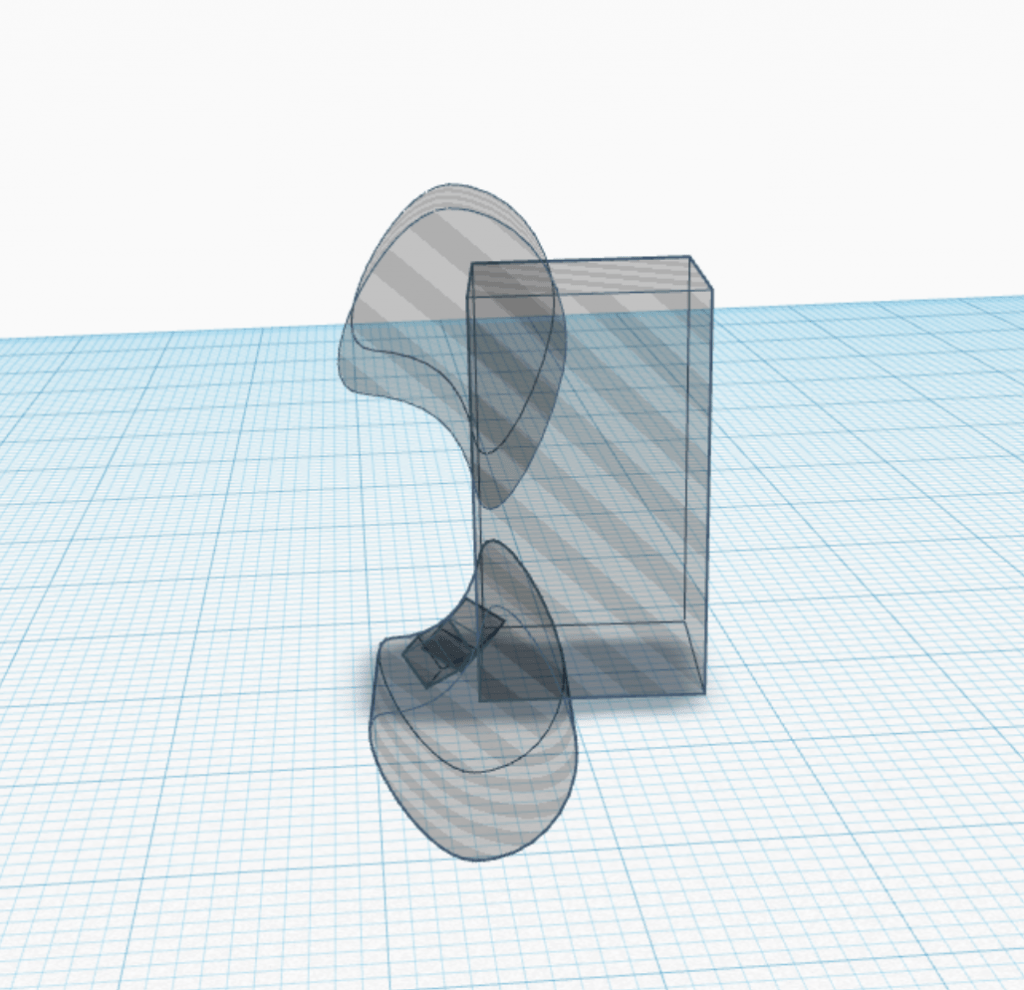

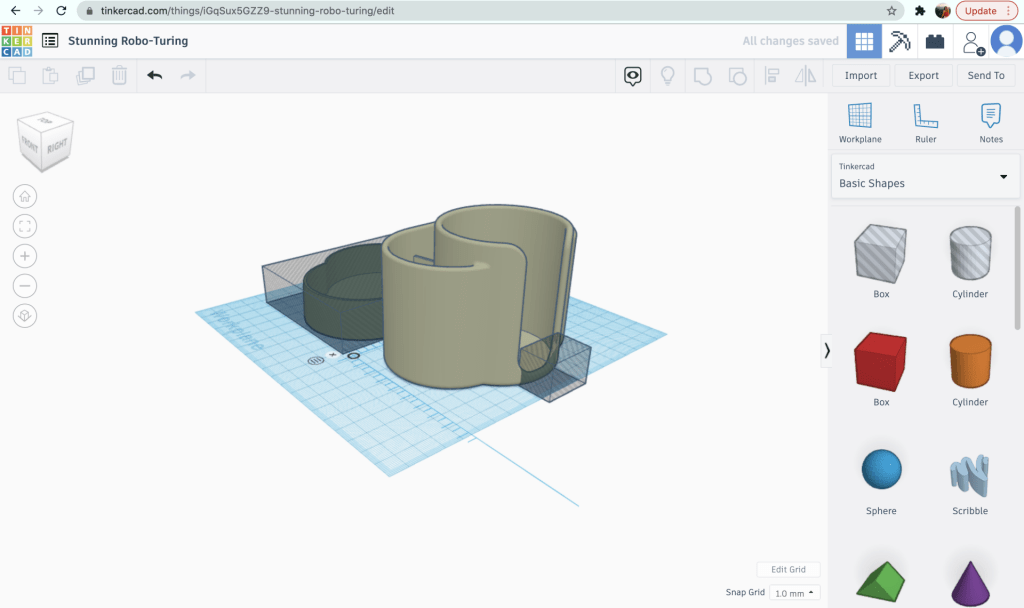

After completing my research and created a concept sketch, I was ready to start designing the object in Tinkercad. There was only one problem: how was I going to design a hand with the available software? The answer to this problem came about while I using an iPad mounted LiDAR camera, paired with the Monocle Structure Scanner application while working on the 3D Bust Scan project. During the process, I realized that I could use the camera and scanning software to create a 3D scan of my hand, which I could import to Tinkercad. With the help of Professor Hooker, I held my hand in a manner that emulated the position of the hand-drawn in the concept sketch in the previous section. After transferring the .OBJ file of my scanned hand onto my computer, I converted it into a .STL file in Tinkercad.

Below are a series of pictures that document the transformation process.

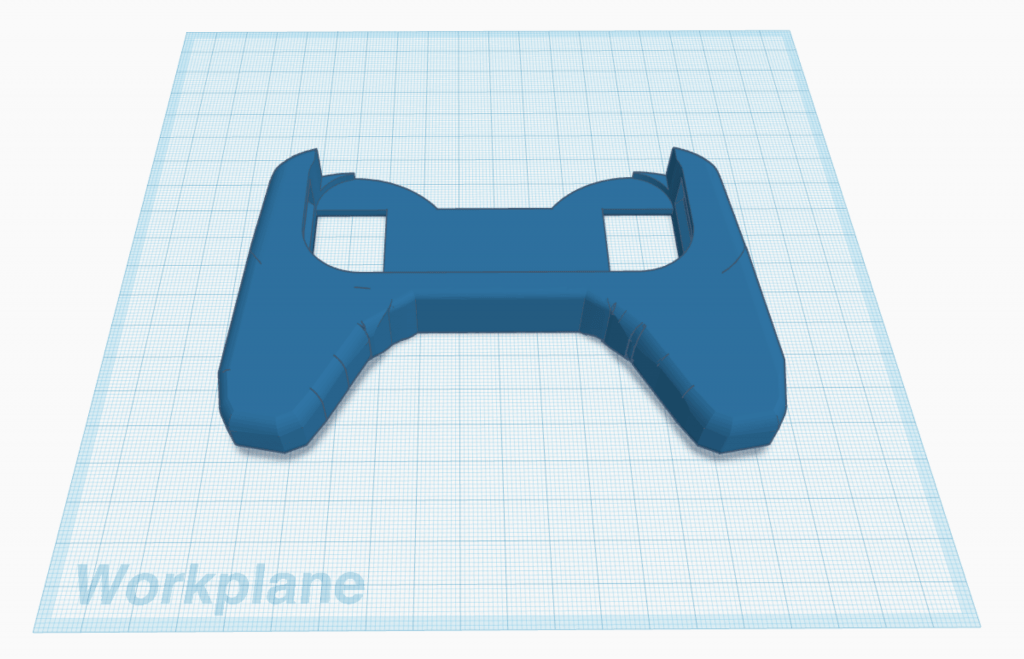

As seen in the pictures above, I had to utilize numerous ‘holes’ in order to isolate my hand. Besides that, the design was pretty straightforward. Thankfully, in Tinkercad’s ‘Making At Home’ list there was a readily available 3D model of a pencil. I merely inserted a cylindrical hole into the pencil to make it hollow, grouped them together, and then positioned the pencil in a way that allowed for the hand to grip it. Finally, I added a saucer where the wrist meets the palm, in order to create a wider and more stable base for the holder.

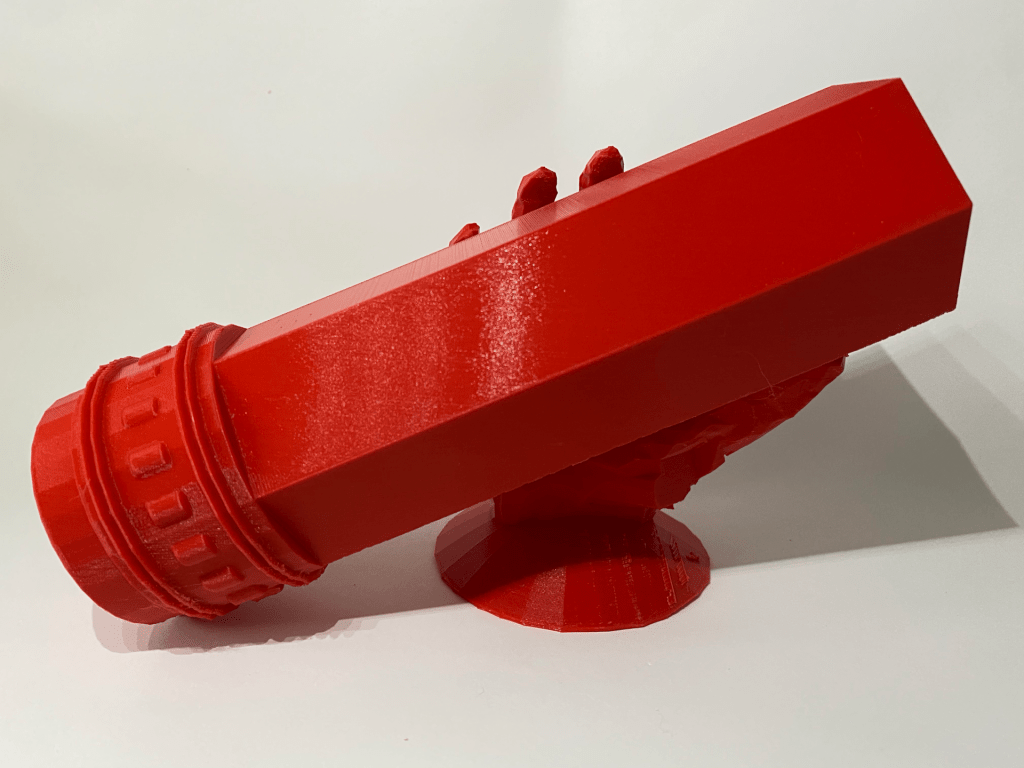

Due to time constraints, I have only been able to print out one iteration. In order to save time and resources, I printed a scaled-down version of the model, to make sure there were no glaring issues regarding its printability. There are a few edits I need to make in Tinkercad and Mesh-mixer, but other than that, I am quite satisfied with how my 3D model turned out. Upon viewing the iframe, one may notice that part of the hand intrudes into the hollow part of the pencil. I tried to address this issue with no success, but am certain this design flaw will be solved by the time I make my final print. I also plan on using Mesh-mixer to better conform the hand’s grip to the pencil.

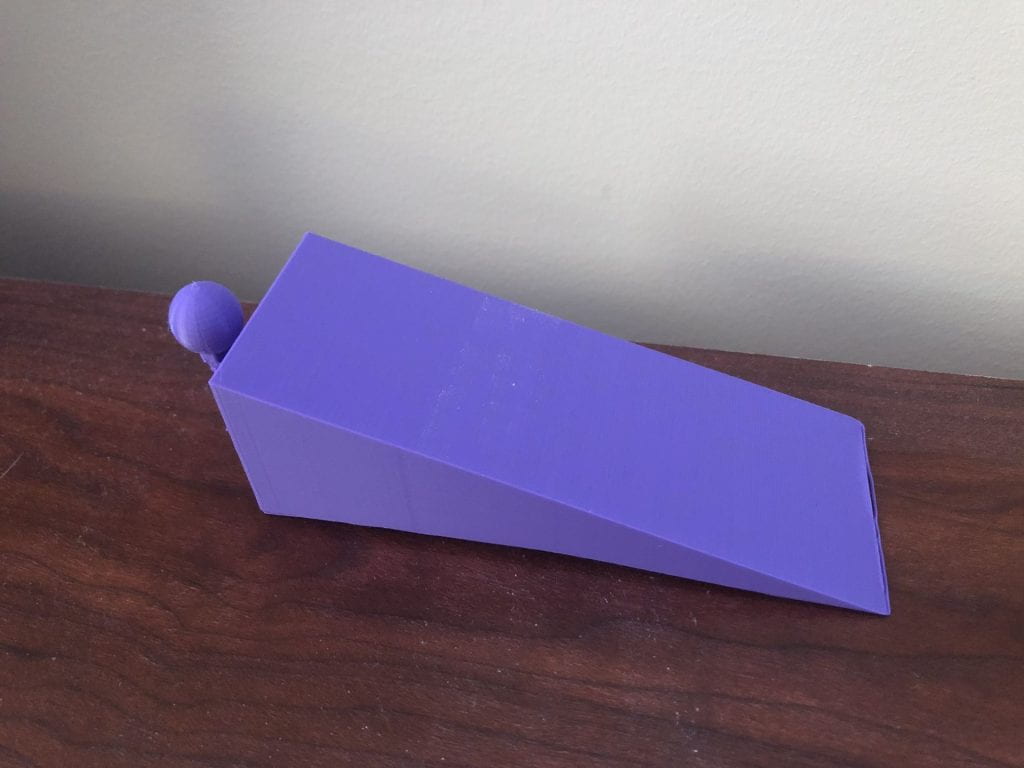

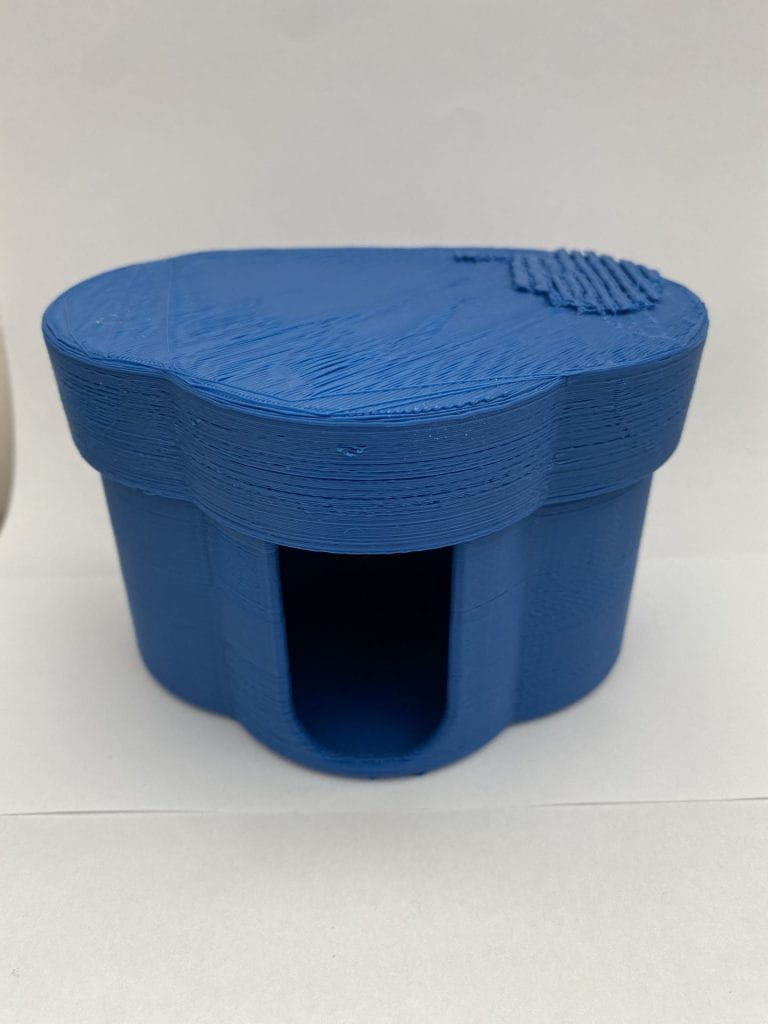

The current model is roughly 4cm in height and 6cm in width. In order to function properly, I will have to print the model on a much larger scale. The only problem that arose during the print was on the printer’s end. As evident in the pictures above, the printer’s under extrusion resulted in the deformation of the pencil’s base and left an unwanted hole as well. In conclusion, this iteration has helped to point me in the direction I need to take, in order to achieve the results I am looking for.

Final Print & Reflection

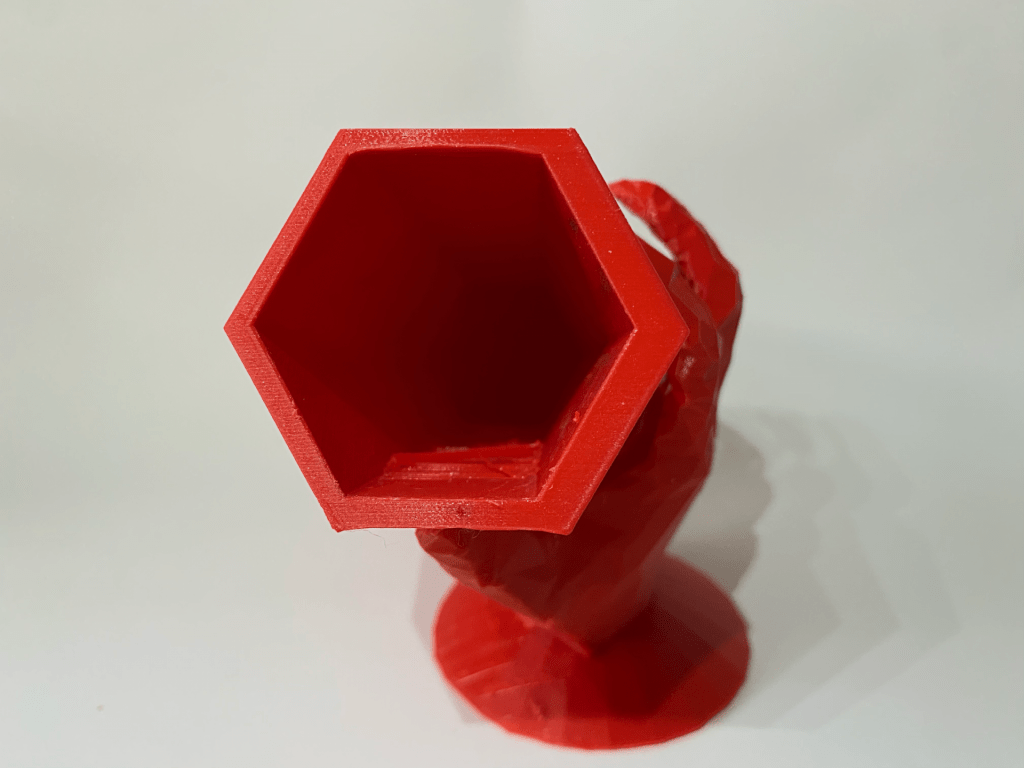

For my final print, I decided to make the ‘pencil’ that the hand is holding much larger, and changed the hole from a cylinder to a hexagon in order to maximize storage space. By widening and lengthening the ‘pencil’ part of the pencil holder, I hoped to ensure that there was enough counterbalance present. This would allow me to house an adequate amount of pencils, without worrying about it tipping over. I also modified the ‘pencil’ part of the pencil holder by making sure that its base would be level with the base of the hand. Although I tried my hand at Meshmixer, I was unable to smooth out the hand or change up the grip to make it conform to the pencil more tightly. I spent the better part of an hour and a half trying to rescan my hand with professor Hooker, but it was to no avail.

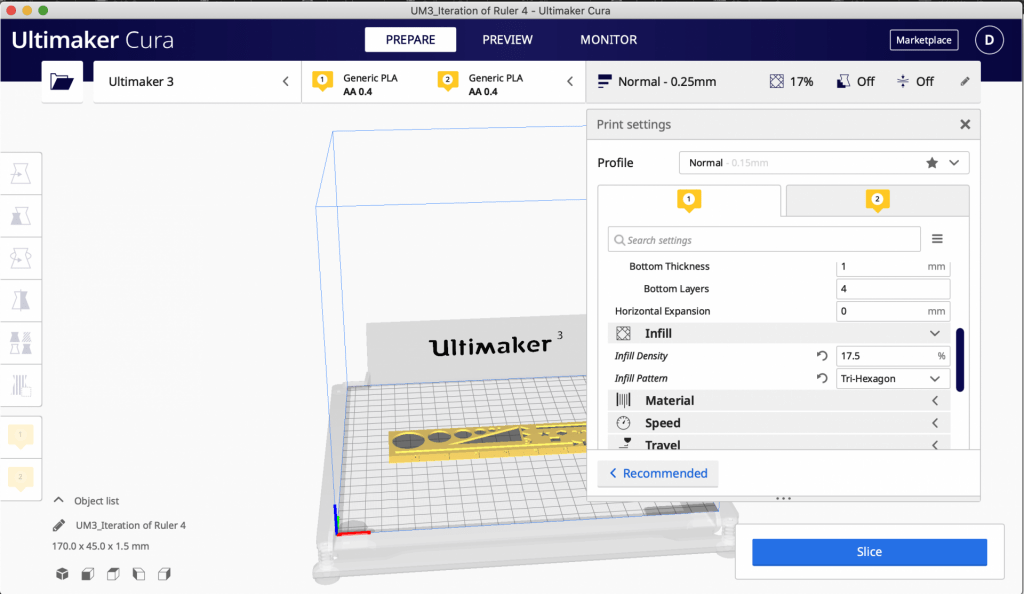

After multiple printing attempts, I still remain unsuccessful in obtaining a finished product. Below is a screen capture of the print settings I used and the estimated printing time. Currently, I am in the process of making my third print. I will have to post an update regarding its outcome. So far, it seems as if the problems stem from over-extrusion and lack of printer cooperation. Unfortunately, this process has garnered more pain than pleasure, but I guess that is all a part of the learning experience. I have been able to avoid any major problems in my previous prints, but that success has not carried over to this project. I am really hopeful that I will be able to obtain a good print by the end of this process.

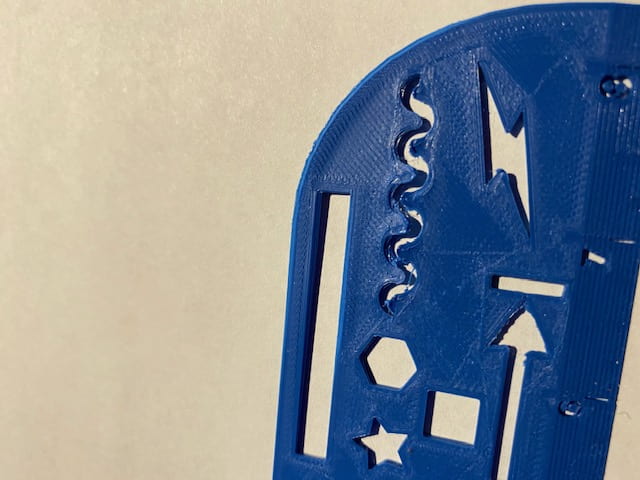

Below are a couple of pictures that capture the various issues I have faced throughout this process.

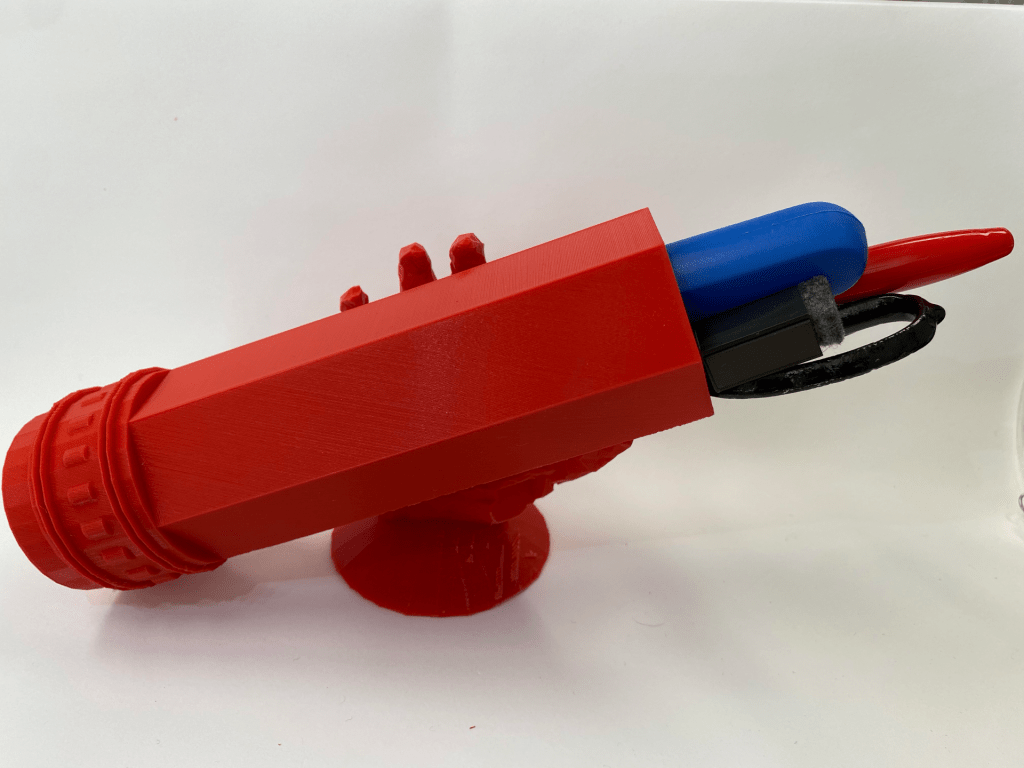

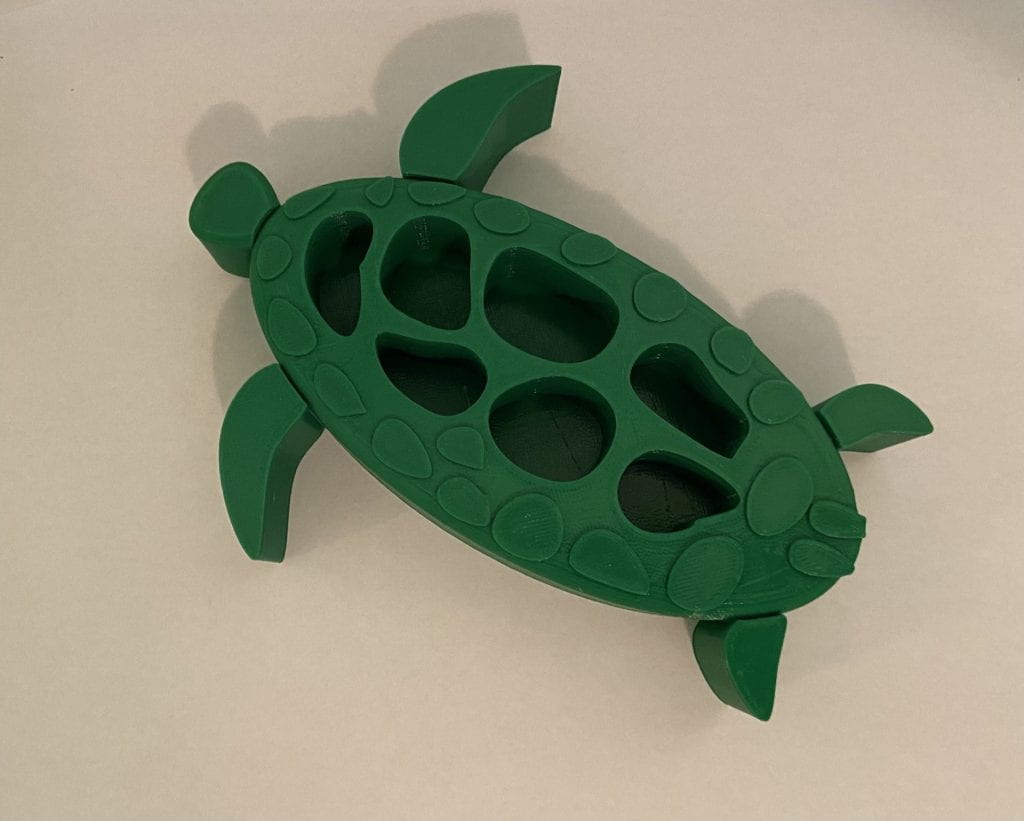

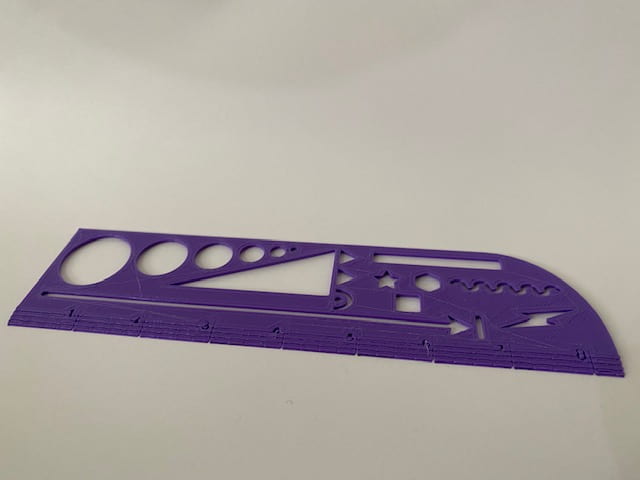

Upon closer inspection, and two failed prints, I realized that the reason for the misprints was due to my incorrect calibration of the print settings. Professor Hooker brought it to my attention that I might have forgotten to add supports to the print settings, which was in fact the case. Upon making this correction, I was able to obtain a successful print of the pencil holder. Below are a few pictures that showcase the successful print.

I purposely made the sides of the holder that come into contact with the hand thicker, in order to ensure that none of the hand bled into the hollow space of the holder. Overall I am pretty satisfied with how the print turned out. Although the third picture makes it seem like objects placed into the pencil holder are easily accessible, thus fulfilling its function, the holder is actually longer than all the mechanical pencils, pens, and highlighters that I own. Unfortunately, this negatively affects its usability to a degree. Other then that

Link to the design: