F|F Research & Concept

This is the original Thingiverse object!

https://www.thingiverse.com/thing:2183259

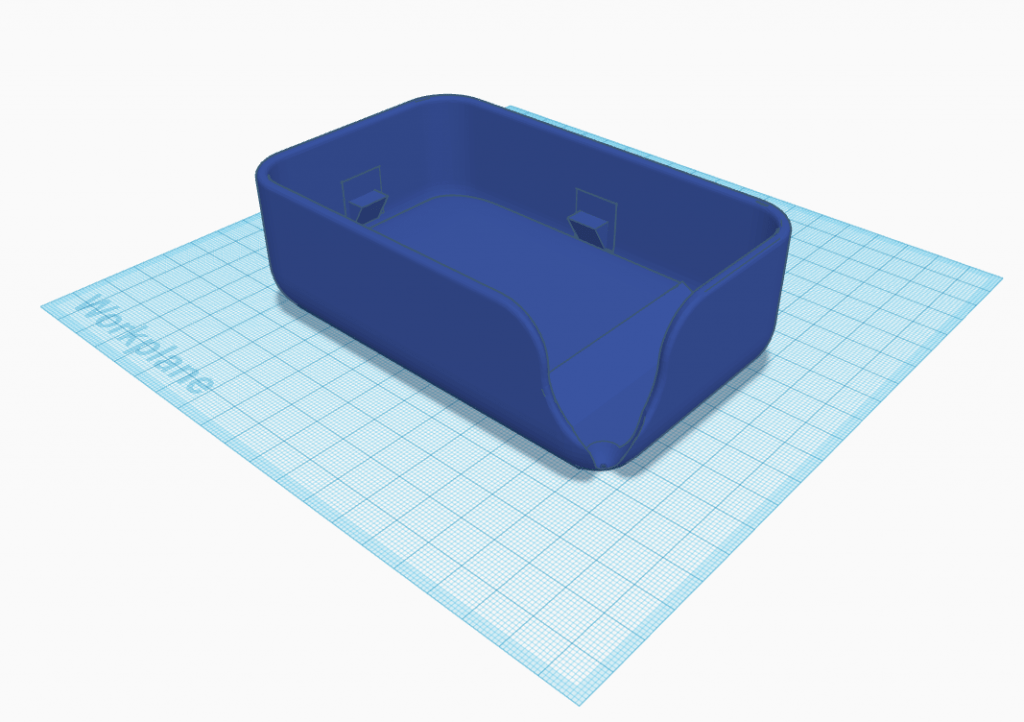

This is a 3D printed plant pot. The purpose of this object is to hold small plants such as flowers or succulents. There are two deep cut-outs that allow space for both the plant and the dirt that it requires in order to grow. The object includes mini stairs for an aesthetic look. This object also allows for the owner to place not one, but two different kinds of plants within the object, which would provide for a more aesthetically pleasing look.

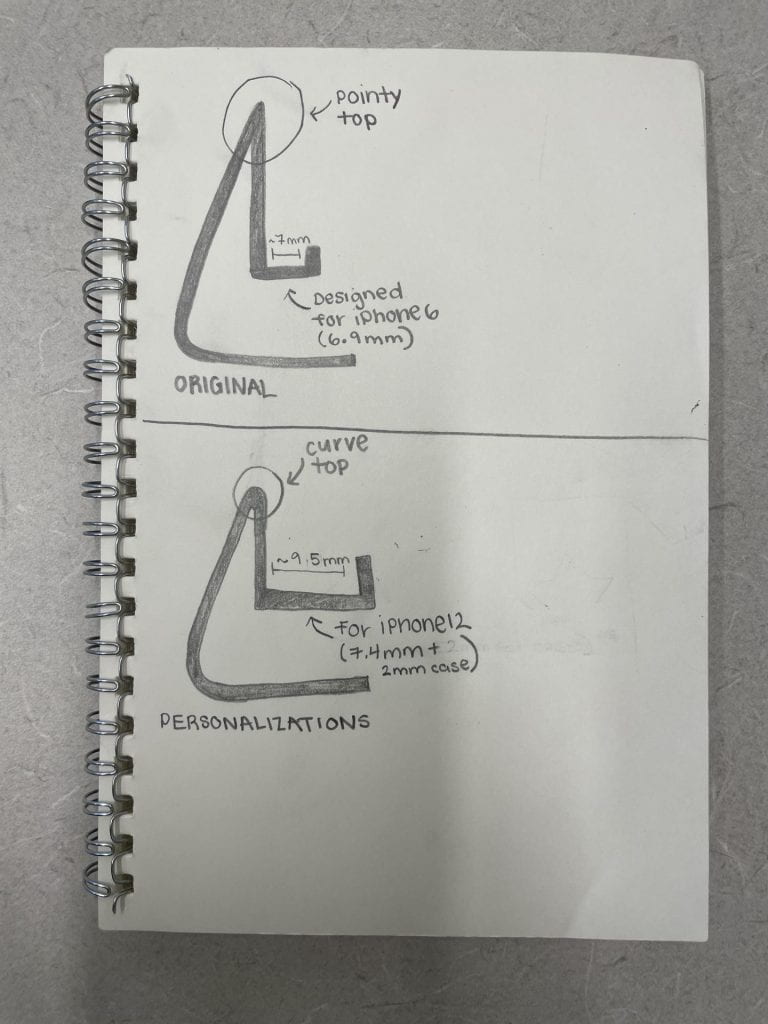

Personalizations & Improvements

I really love the design of this object and I think that aesthetically it looks really good. One improvement that I think would really help would be the addition of small holes in the middle wall. This would allow for even distribution of water and allow for wiggle room, should you over water one of the plants. The small holes would give you the added luxury of only having to water one side. Another change I made was that I made the object 25% smaller. I thought that this would be beneficial in regards to printing time and it would make the object that much more versatile, you could put it in so many small places! Lastly, I made an aesthetic change, I thought the pot might look more cohesive and interesting if the first set of stairs went into the object itself.

F|F Iterations

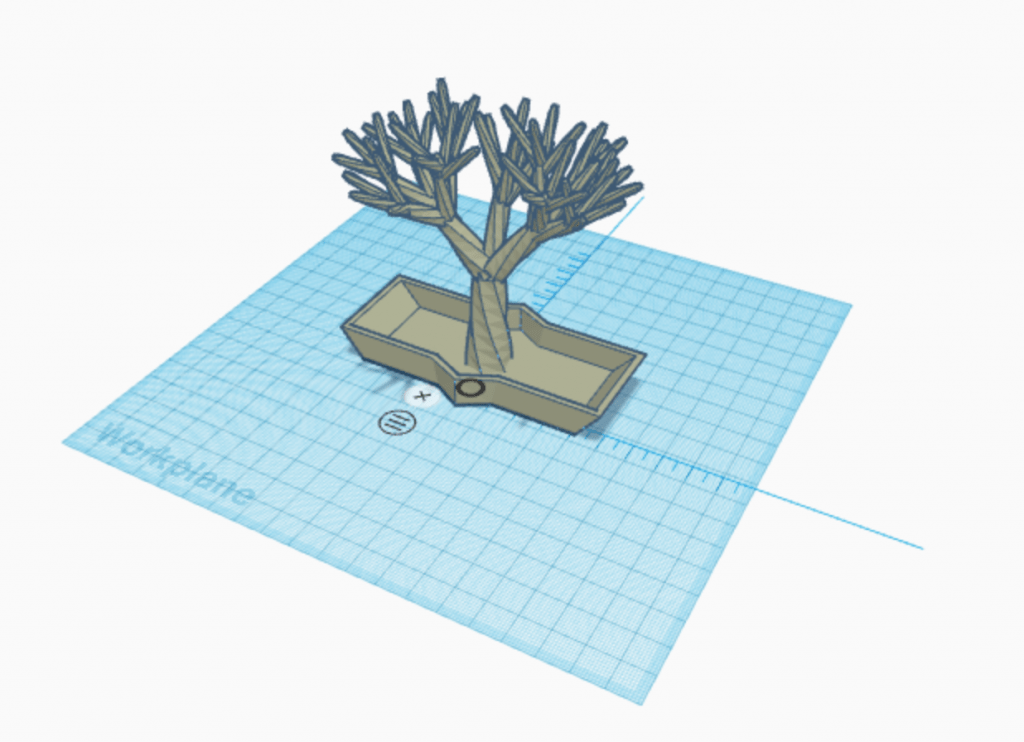

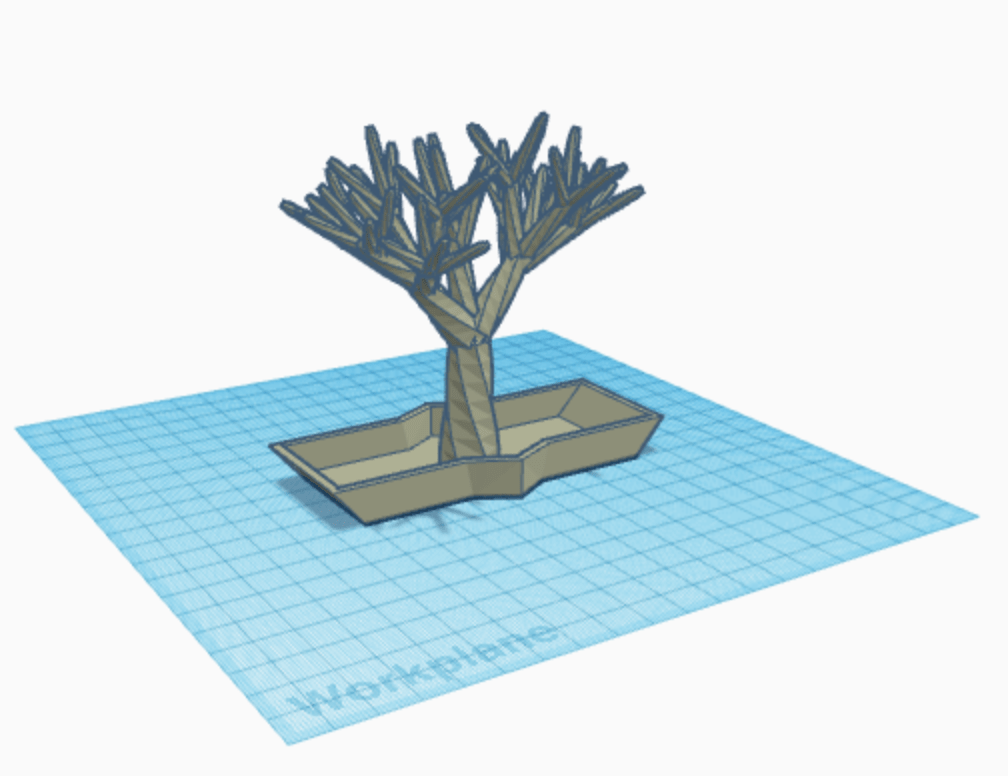

Original Object by @AndresQuijas on Thingiverse

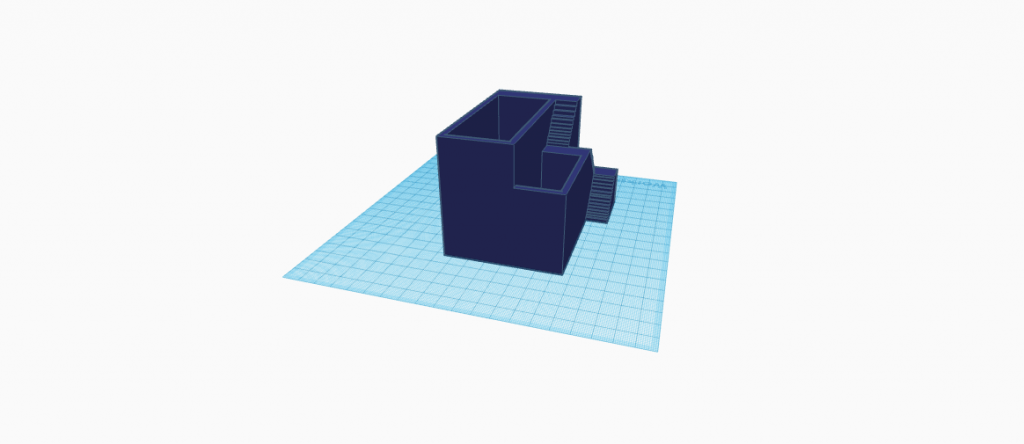

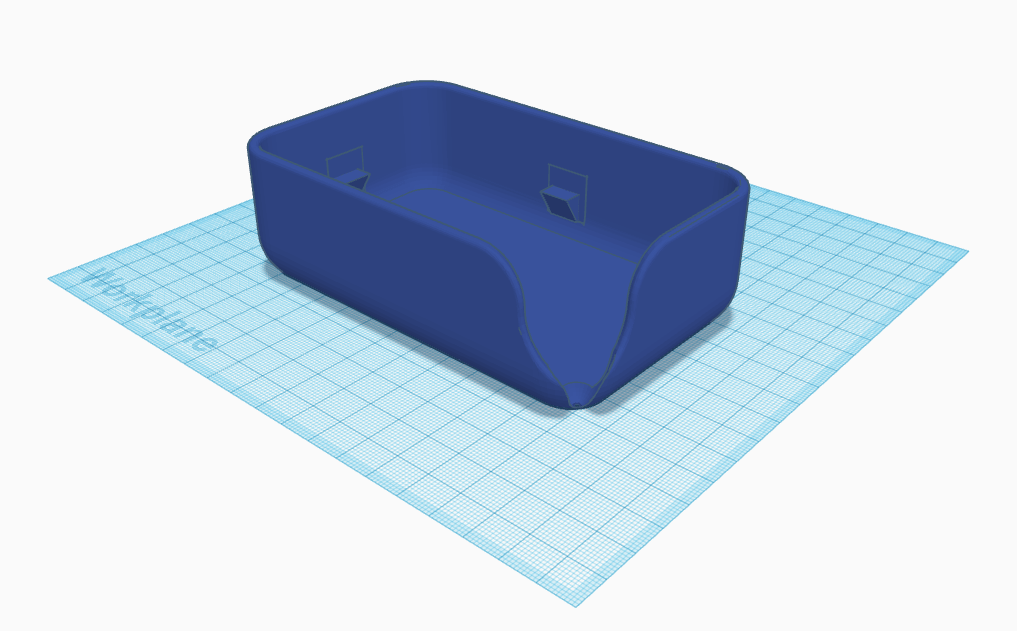

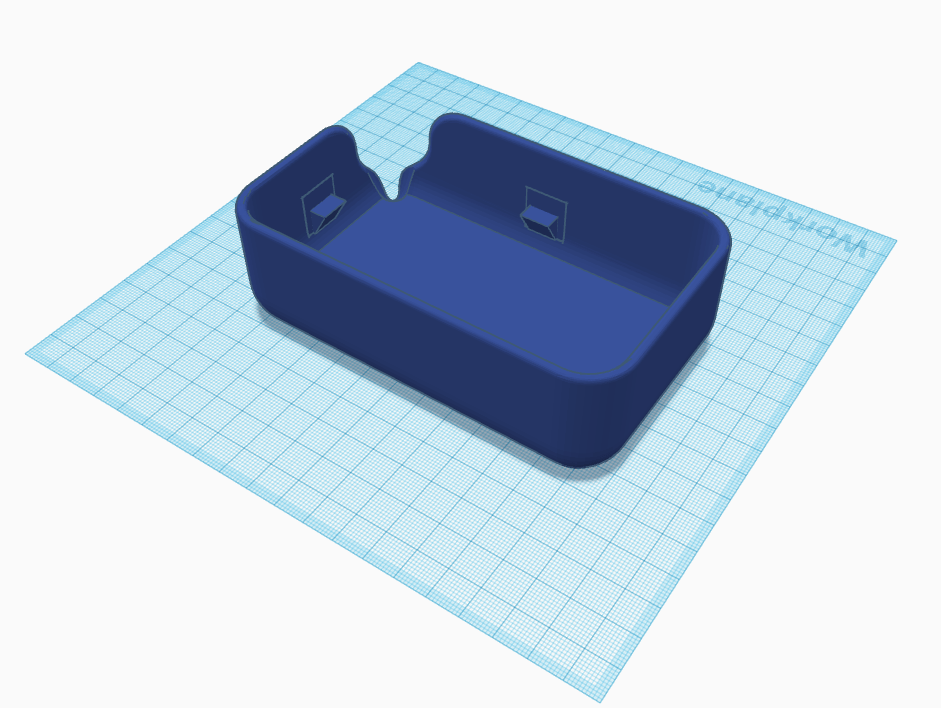

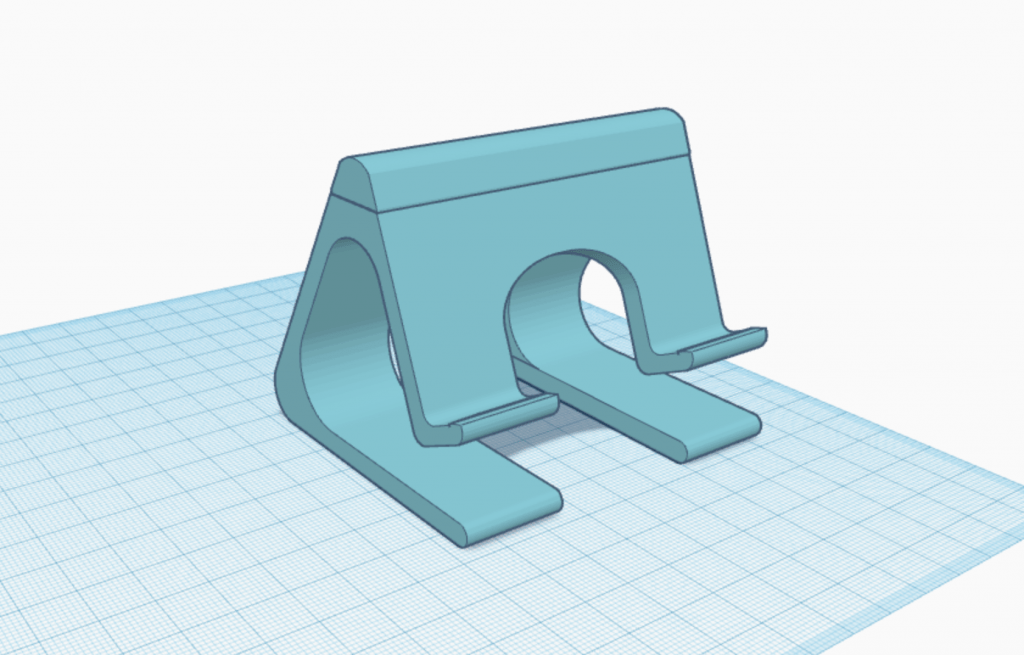

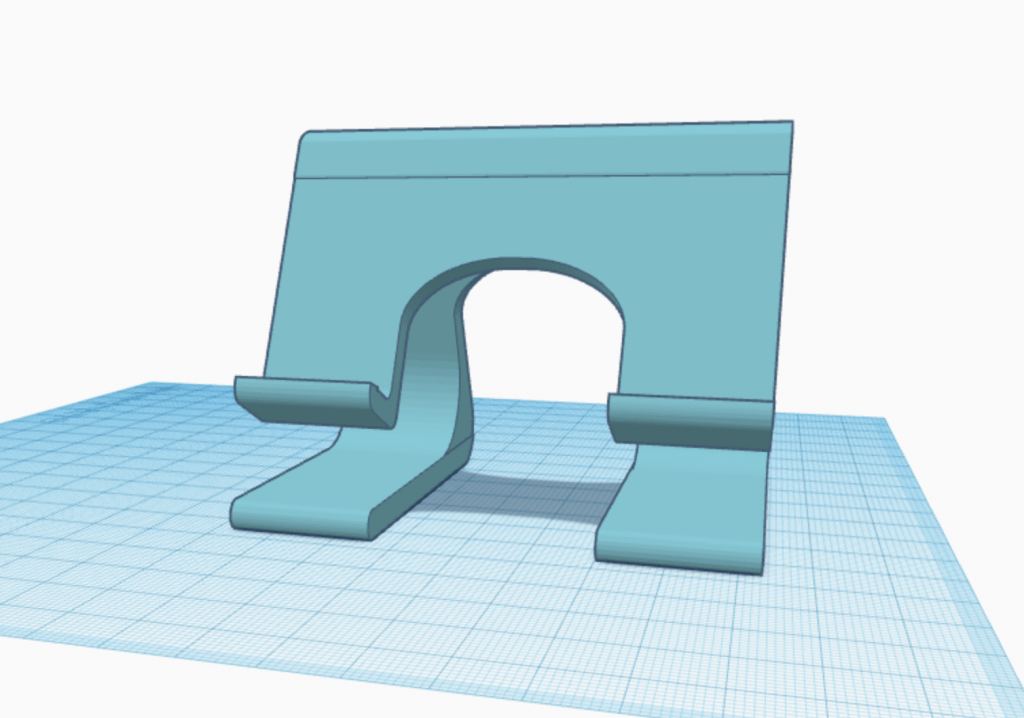

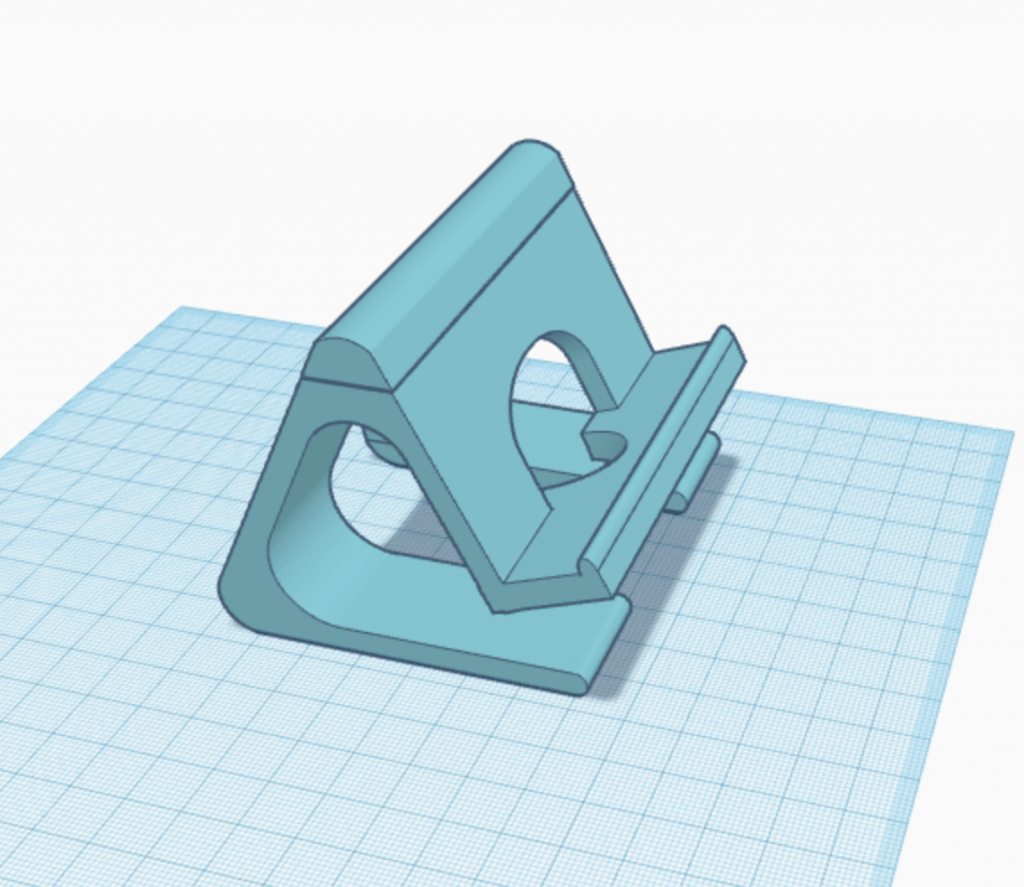

Tinkercad Iterations

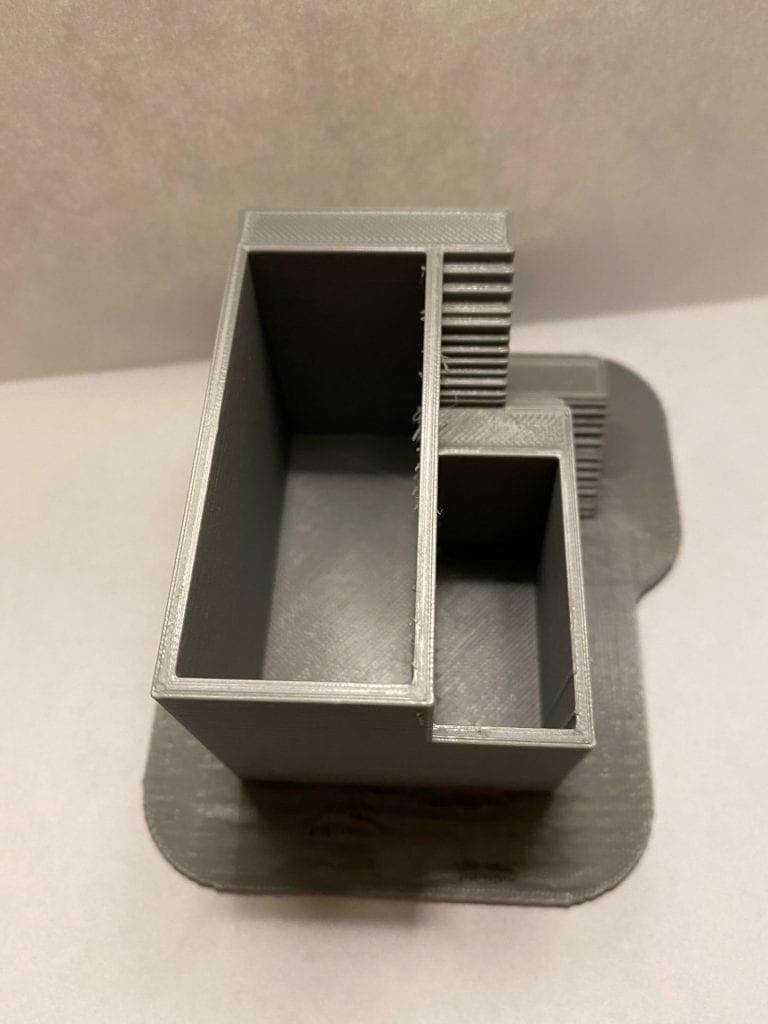

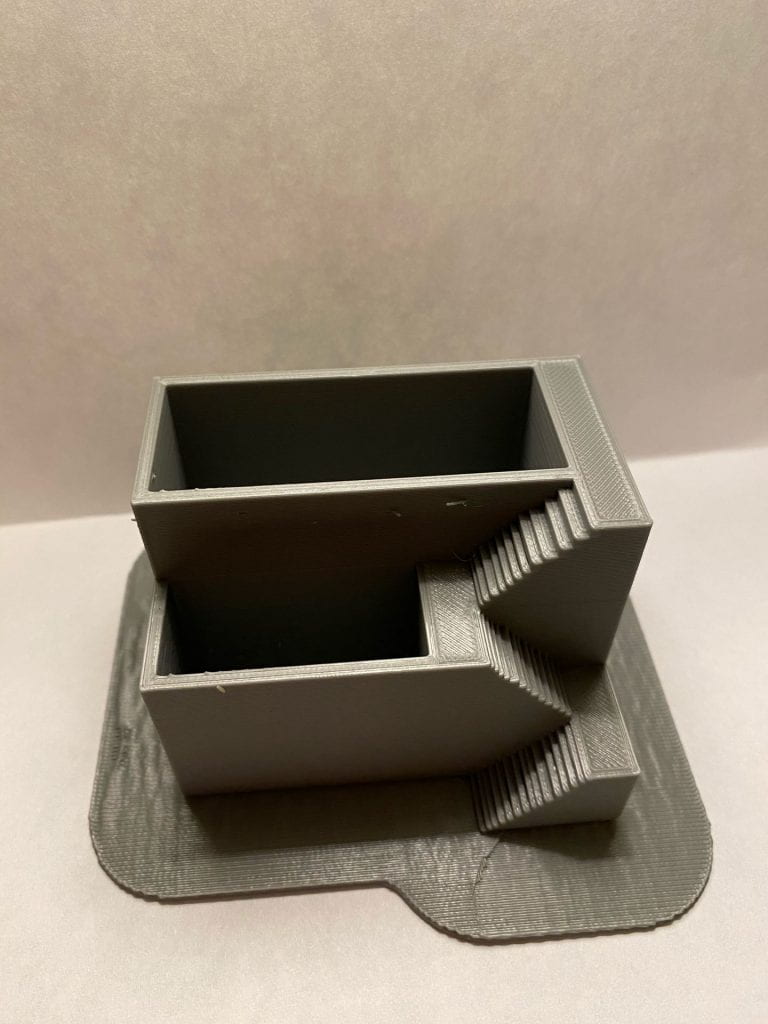

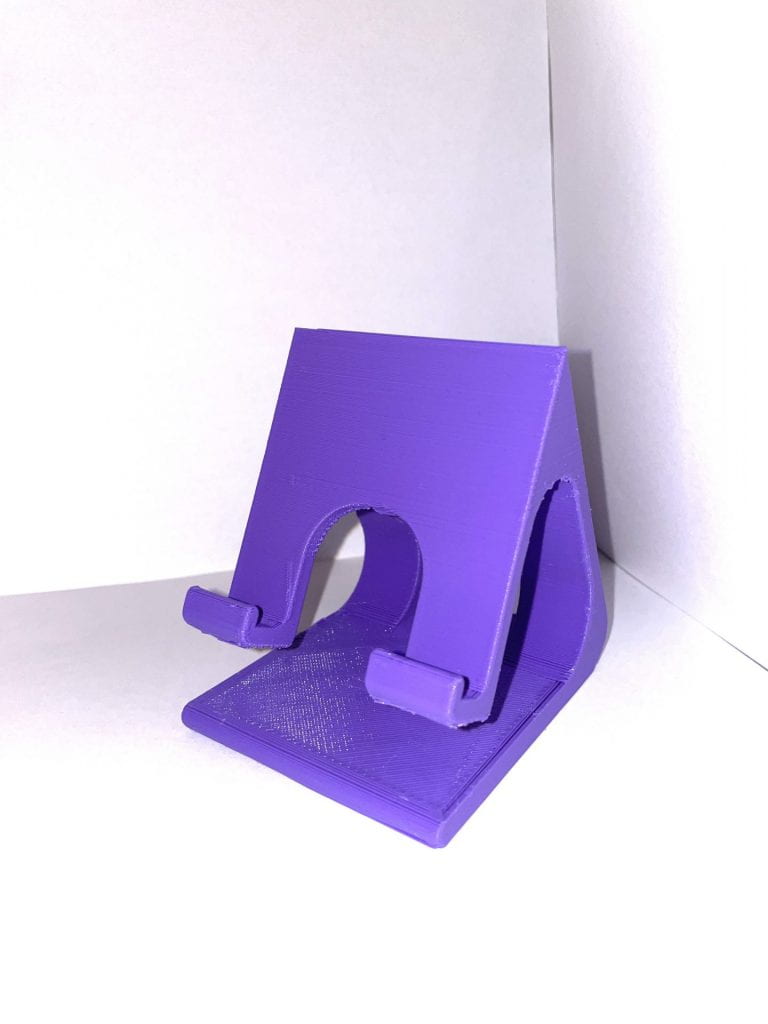

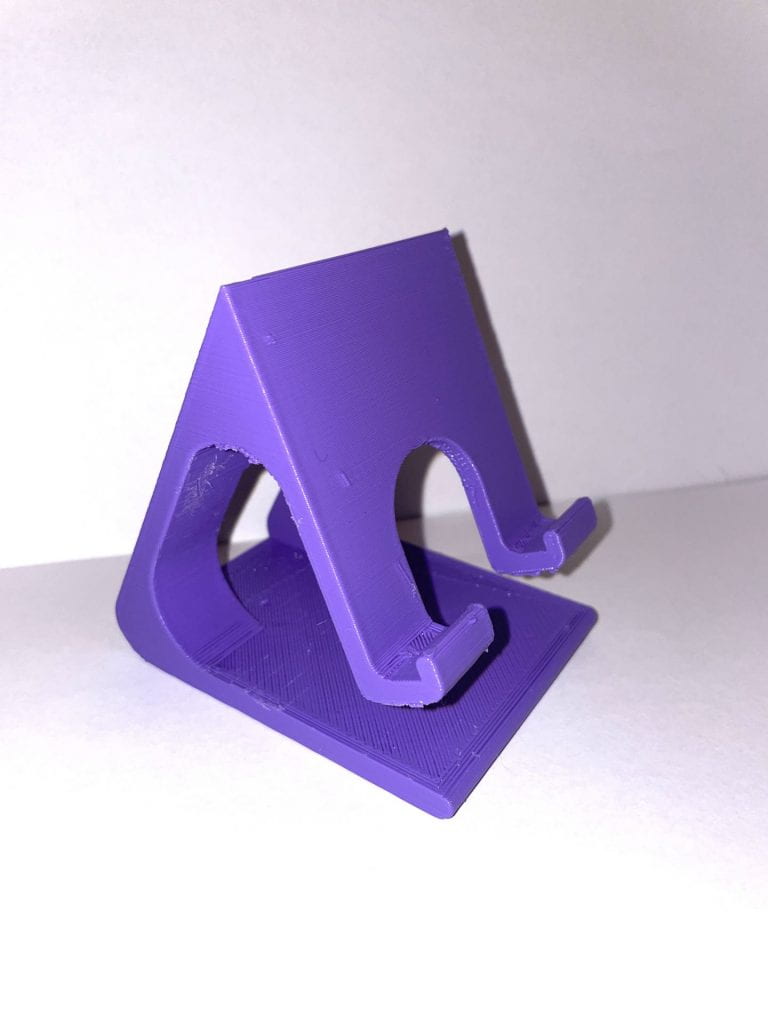

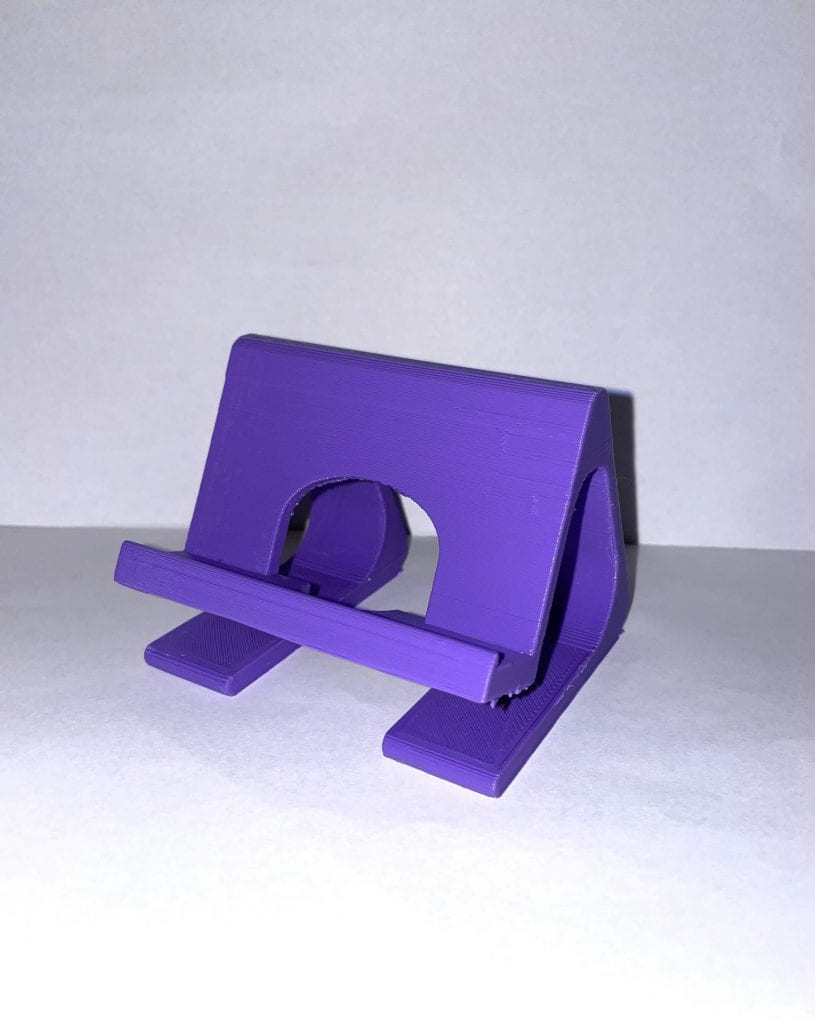

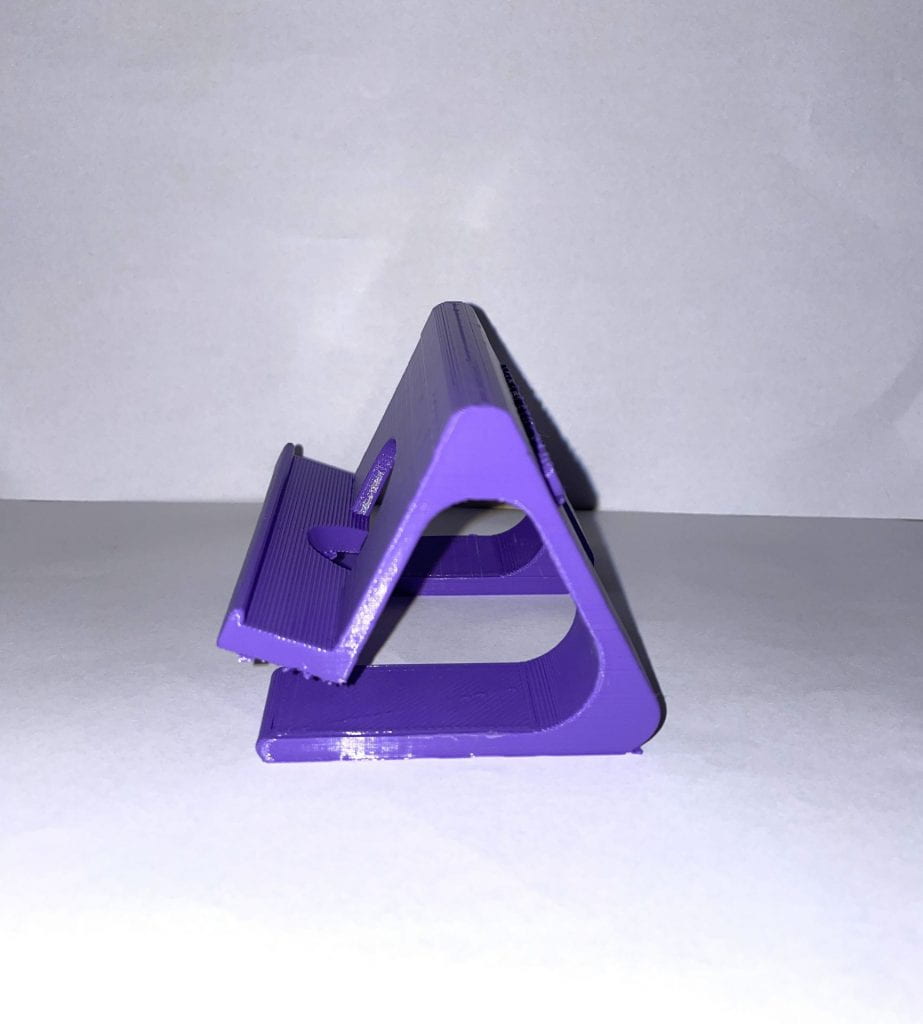

3D Print Iterations

I found this process so exciting and interesting! I began with printing the original object, but when I put it in Cura it was going to take a day and a half to print. After talking with Dr. Hooker I decided to scale it down by 50% with a .2 layer height and 5% infill. With this, I was able to cut down the time it would take to print by a lot. After printing the first print, I realized that it came out with a bottom piece part attached to it. I wasn’t really too fond of the way it looked and also thought it would add to the print time. The next day when I went to print my object with iterations, I realized that the different printer I was using printed even faster! As it printed I watched and I found that the printer I switched to did not add that bottom piece, which I think works better for the object aesthetically.

When I was adding iterations in Tinkercad I worried my iterations would be uneven, but eventually, I got it down. When I printed the second object, it came out perfect. I did end up making what I would call a “happy mistake”. When I printed the altered object, the holes weren’t completely hollow, but I actually liked the way it looked a lot better. I also think that it would function better for plants. This way the water can seep through slowly if you over water one side and it also makes the holes in the object more discrete. In addition to this, I really liked the way the object looked without the third set of stairs and the extension of the lower crevis.

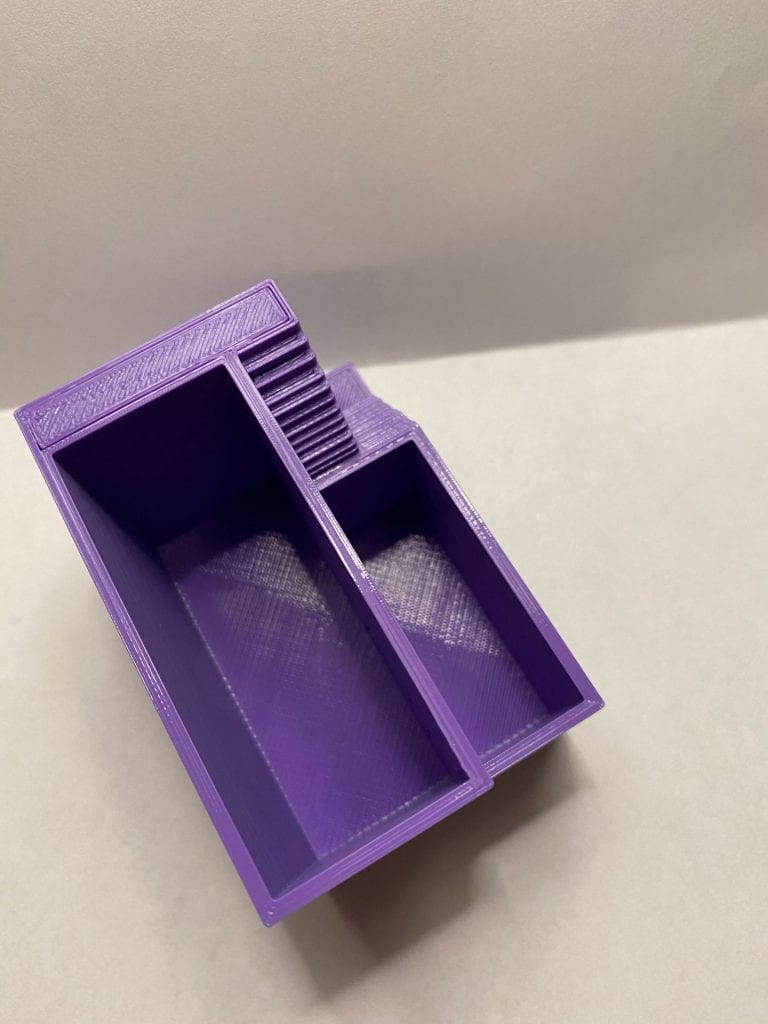

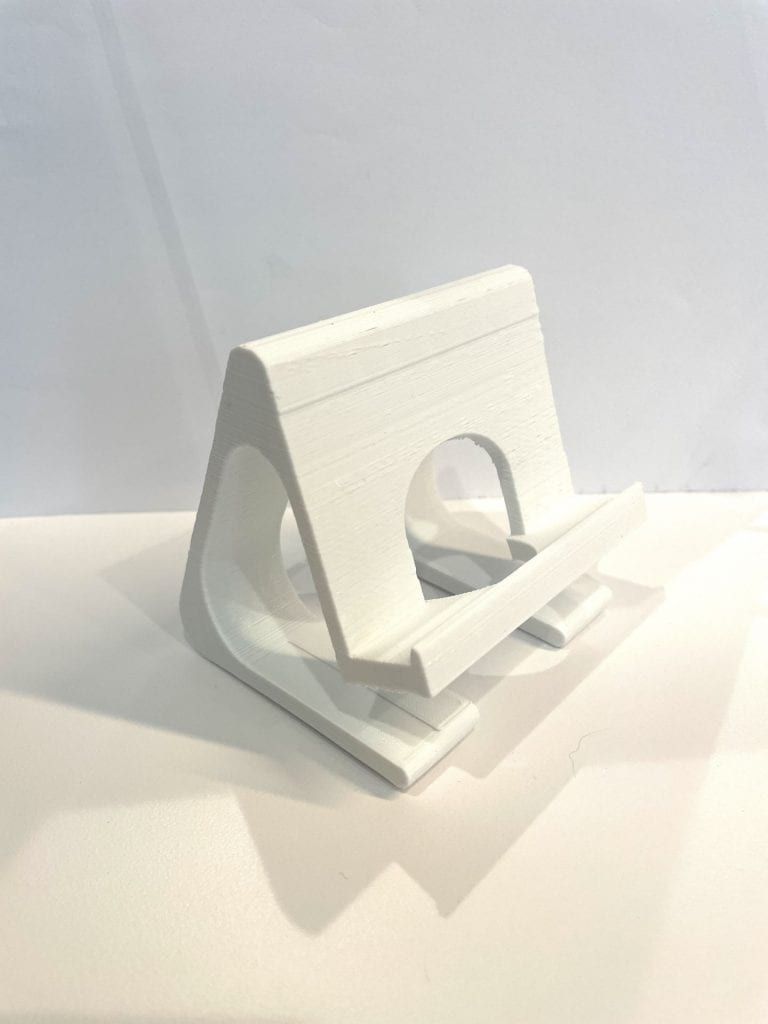

F|F Final Print & Reflection

This is my final remix of AndresQuijas flower pot, more about my remix can be found on Thingiverse.

Reflection

Throughout the process of working on this project, I have been able to learn so much about 3D printing that I never knew before. I started out feeling discouraged when I realized that the specific flower pot I chose to print would take a day and a half to print. With help from Professor Hooker, I was able to adjust aspects of the print in order to get the printing time down. I started by adjusting the sizing by 50% with 0.2 layer height, and 5% infill. After printing the original in with those adjustments, I printed my iterations with them as well. I was content with the way my iterations came out and for my final print I wanted to make the print true to size, so I did. My final print is the actual size that the piece was supposed to be, so I was able to put actual plants in the print, which was so cool. I enjoyed seeing the print “come to life” and be put to real use. I watered the plants on one side and check the soil to see if the holes I put in were doing their job, and it worked! Through this project, I have learned that 3D printing is a big game of trial and error, so when I got to my last print and was satisfied with it, it was a really gratifying feeling.