Ben and I decided to make a portable gumball machine with a revolving dispenser. We thought we could challenge ourselves with moving parts. Although the individual pieces of our machine are relatively simple, we think that the printing and assembly of our machine might prove to be somewhat difficult. We have essentially 2 pieces connected around another revolving piece in the middle, and have not decided whether the best course of action would be to pause the print to add the revolving mechanism, or to print everything separately and add something after the fact to adhere the 2 connected pieces. We are leaning towards the latter. We’re also worried about possible cloggage within the revolving part, so we’ve added some safeguards within, and will have to tinker around with the design more as we see what works and what doesn’t.

Cheers!

FIRST DRAFT PRINT

Our first print was a huge success in our book. I think we did a really good job initially of designing our print, so that, somewhat to our surprise, it came out pretty much exactly how we wanted it to. Especially surprising is the fact that even the moving components work according to our specifications. For our initial print, we were worried that some of our components might not have fit well together, considering we printed every part separately to better accommodate the movement of our independent parts. However, even after we decided to scale down our model for ergonomic reasons, our first print turned out perfectly.

ITERATING THE DESIGN

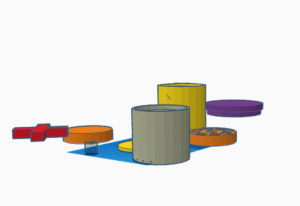

As far as continuing our design, we decided that we needed to create a lid that would pop in and fit well onto our gumball machine, as seen in our screenshot. It was tricky to design the lid so that it would fit tightly without being too big.

FINAL PRODUCT

Our original lid was just a little bit small to hold tightly to the rest of the gum ball dispenser. Instead of reprinting another lid and having it potentially not fit again, we decided to use a rubber band affixed to the lip of the lid, which effectively holds the top in place with a push and a twist. We also assembled our moving parts by fully assembling the dispenser and then glueing the axis of our base into our pre-made notch in the storage piece. Our first test objects were skittles, which proved to jam the dispenser because of their “flat” design. We eventually found that the center pretzel of pretzel m&ms were both the perfect size and perfect sphericalness to fit our design. Visit our thingiverse page to download the files necessary to make this gumball machine: https://www.thingiverse.com/thing:3133139

Recent Comments