From Artifact to Internet

JMU’s First 3D Art Collection

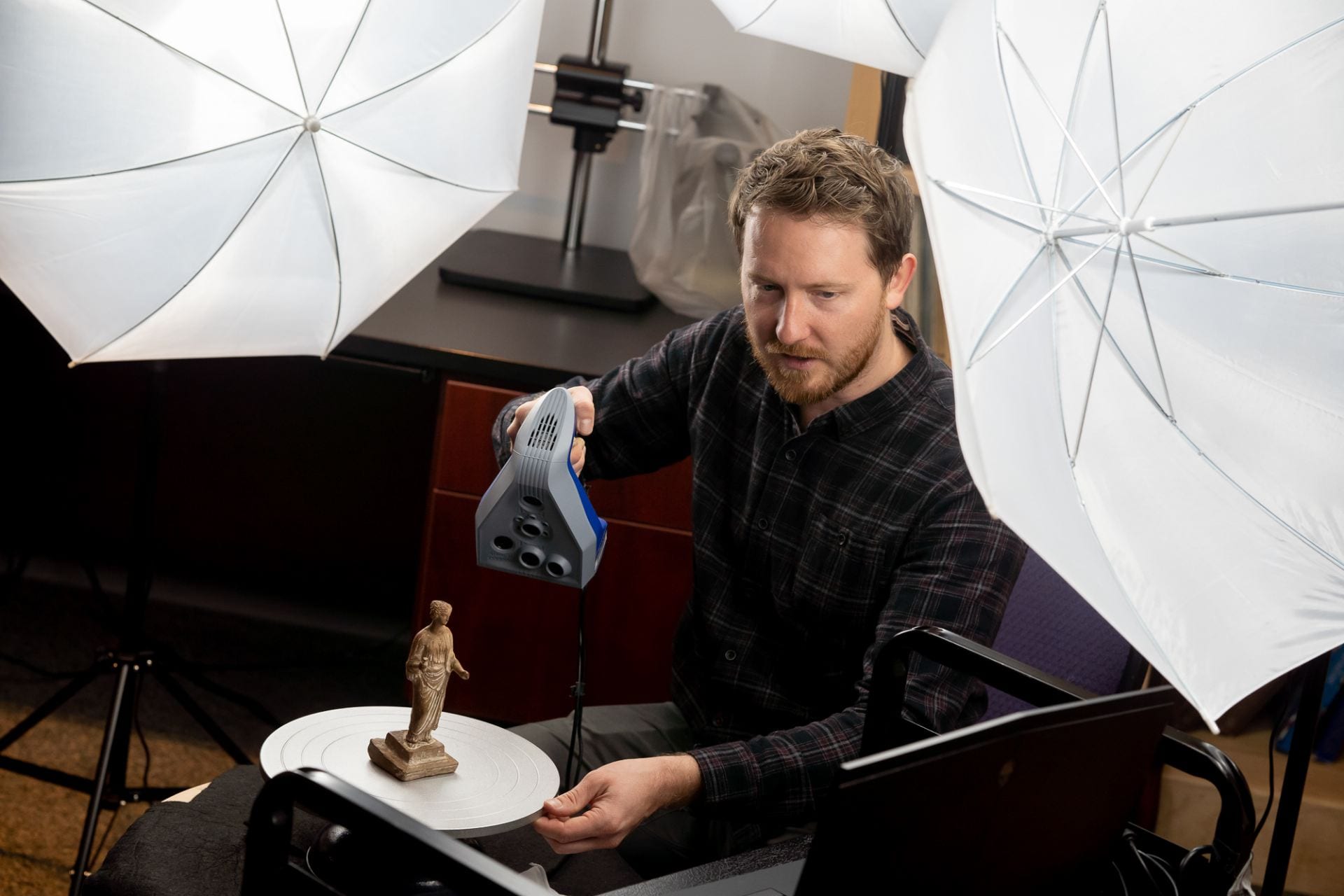

Working in collaboration with JMU Libraries, the Madison Art Collection has created JMU’s first “3D Art Collection,” which includes over 30 ancient artifacts as downloadable 3D models. The lengthy process involved using the latest 3D scanners from Artec and the online publishing platform SketchFab. As most of these artifacts are fragile and some are limited to the total amount of light they can be exposed to, this 3D collection makes them accessible to the public 24/7 and 365 days a year. These virtual copies can also be 3D printed and studied up close by those with visual impairments.

The Process

The digitization process involves using 3D scanners from Artec, which capture the shape and surface texture of the objects being scanned. A

3D Printing

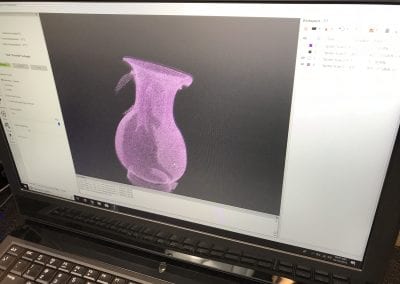

After a 3D scan is completed, it is rendered and exported into a common file type, such as .obj or

Technologies Involved in the Process

Artec Spider:

The scanner’s ability to render complex geometry, sharp edges and thin ribs sets our technology apart. It is an ideal industrial 3D scanner for high resolution capturing of objects such as molding parts, PCBs, keys, coins or even a human ear, followed by the export of the final 3D model to CAD software. — Artec Space Spider

Artec Eva:

Sketchfab:

Tinkercad:

Ultimaker 3:

Formlabs Form 2: